Cable1 (PDF)

File information

Title: Microsoft PowerPoint - Cable1.ppt

Author: RKing

This PDF 1.4 document has been generated by PScript5.dll Version 5.2 / Acrobat Distiller 6.0 (Windows), and has been sent on pdf-archive.com on 14/04/2012 at 00:55, from IP address 82.82.x.x.

The current document download page has been viewed 985 times.

File size: 54.2 KB (2 pages).

Privacy: public file

File preview

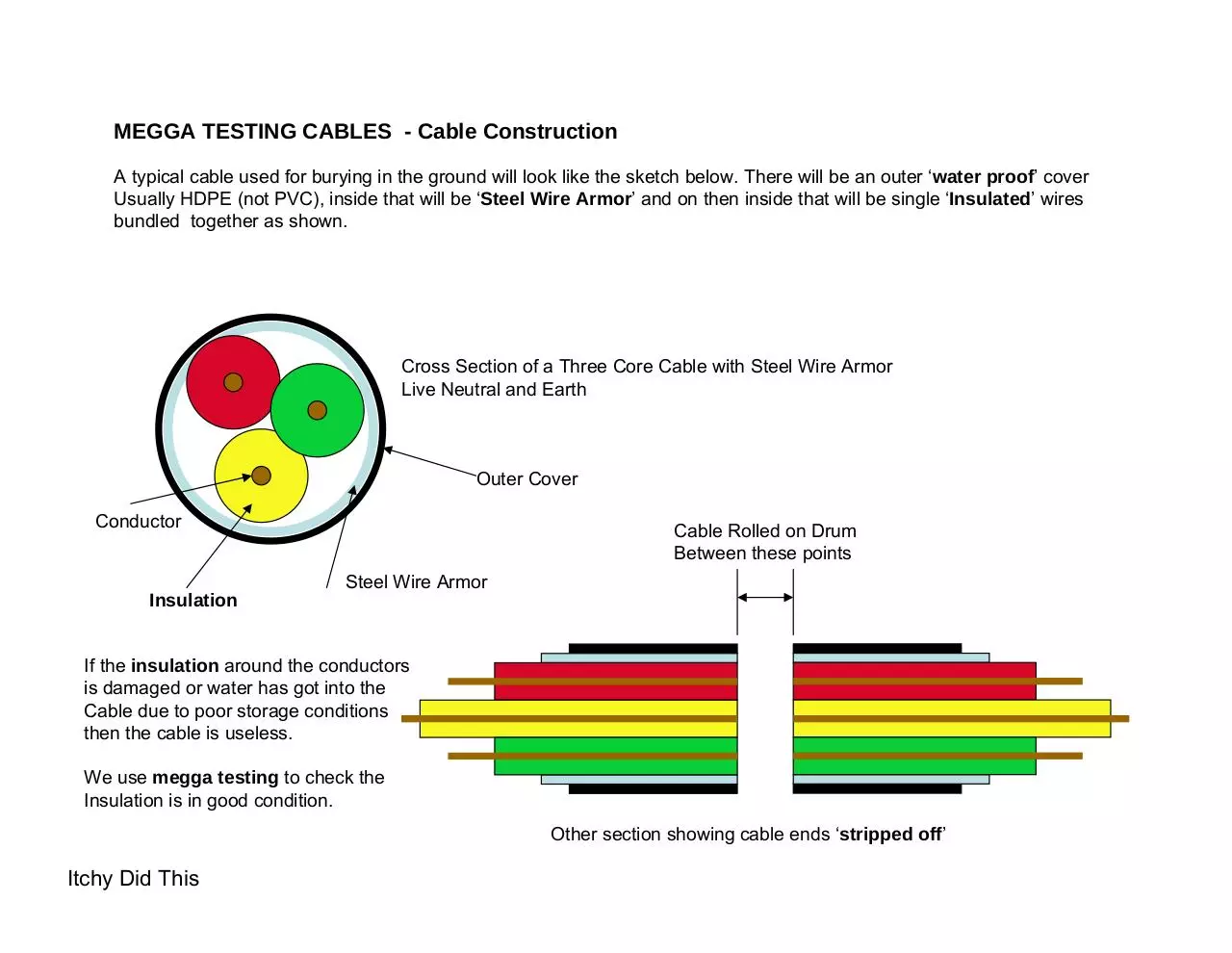

MEGGA TESTING CABLES - Cable Construction

A typical cable used for burying in the ground will look like the sketch below. There will be an outer ‘water proof’ cover

Usually HDPE (not PVC), inside that will be ‘Steel Wire Armor’ and on then inside that will be single ‘Insulated’ wires

bundled together as shown.

Cross Section of a Three Core Cable with Steel Wire Armor

Live Neutral and Earth

Outer Cover

Conductor

Cable Rolled on Drum

Between these points

Steel Wire Armor

Insulation

If the insulation around the conductors

is damaged or water has got into the

Cable due to poor storage conditions

then the cable is useless.

We use megga testing to check the

Insulation is in good condition.

Other section showing cable ends ‘stripped off’

Itchy Did This

Megga Testing works by sending a very high voltage down the cable and checking to see if any of the electricity leaks

across the insulators. The principle is that very high voltages will cause insulators to break down – It’s a bit like

over inflating a car tire to check for air leaks.

Safety Note: Megga Testers work at very high voltage, they can give you a nasty electrical shock. Do not touch the

connectors or wires when megga testing a cable. Never test a cable if it is connected to anything, always disconnect and

Strip-Off both ends.

PRE-PURCHASE TEST

Before you buy the cable, and before the cable is cut off the drum

get both ends of the cable stripped off (as shown on page one)

Connect the Megga Tester to cores A and B as shown,

now make sure you are not touching the leads or wires

Press Test and record the reading.

Now move the black wire to C and test between A and C

Repeat until you have tested between A and all other points

D

C

A

Now move the red wire to B and test

between B to A , B to C and B to D

Then move to C and repeat.

B

All reading should be infinity ∞ resistance

or at least Megga Ohms MΩ

Any reading recorded below 1M Ω

suggests the cable Is damaged and useless.

TEST

PRE-BACKFILL TEST

Repeat these tests after you have put the cable in the ground, but before you back fill the cable trench. This way you

Don’t have to dig up the cable again if it is damaged during installation

Itchy Did This

Download Cable1

Cable1.pdf (PDF, 54.2 KB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000040023.