Asawa Insulation COMPANY PROFILE (PDF)

File information

Title: Slide 1

Author: My Computer

This PDF 1.5 document has been generated by Microsoft® PowerPoint® 2010, and has been sent on pdf-archive.com on 05/03/2013 at 15:23, from IP address 61.95.x.x.

The current document download page has been viewed 2106 times.

File size: 3.86 MB (41 pages).

Privacy: public file

File preview

HVAC DUCTING SYSTEM,

UNDERDECK / OVERDECK INSULATION,

FALSE CEILING, COLD STORAGE

Company Profile

Asawa Insulation Pvt. Ltd. (AIPL) is the first

company

in

India

(Mumbai)

to

manufacture Pre-Insulated Panels (PIRPolyisocyanurate) and Accessories under

the brand name of SMART Panels. AIPL

has a state-of-art manufacturing facility

having installed capacity of 15,00,000

sq.m per annum.

We offer complete solutions from supply of SMART Panels with Accessories to

Fabrication & Installation and after sales service.

SMART (PIR) Panels

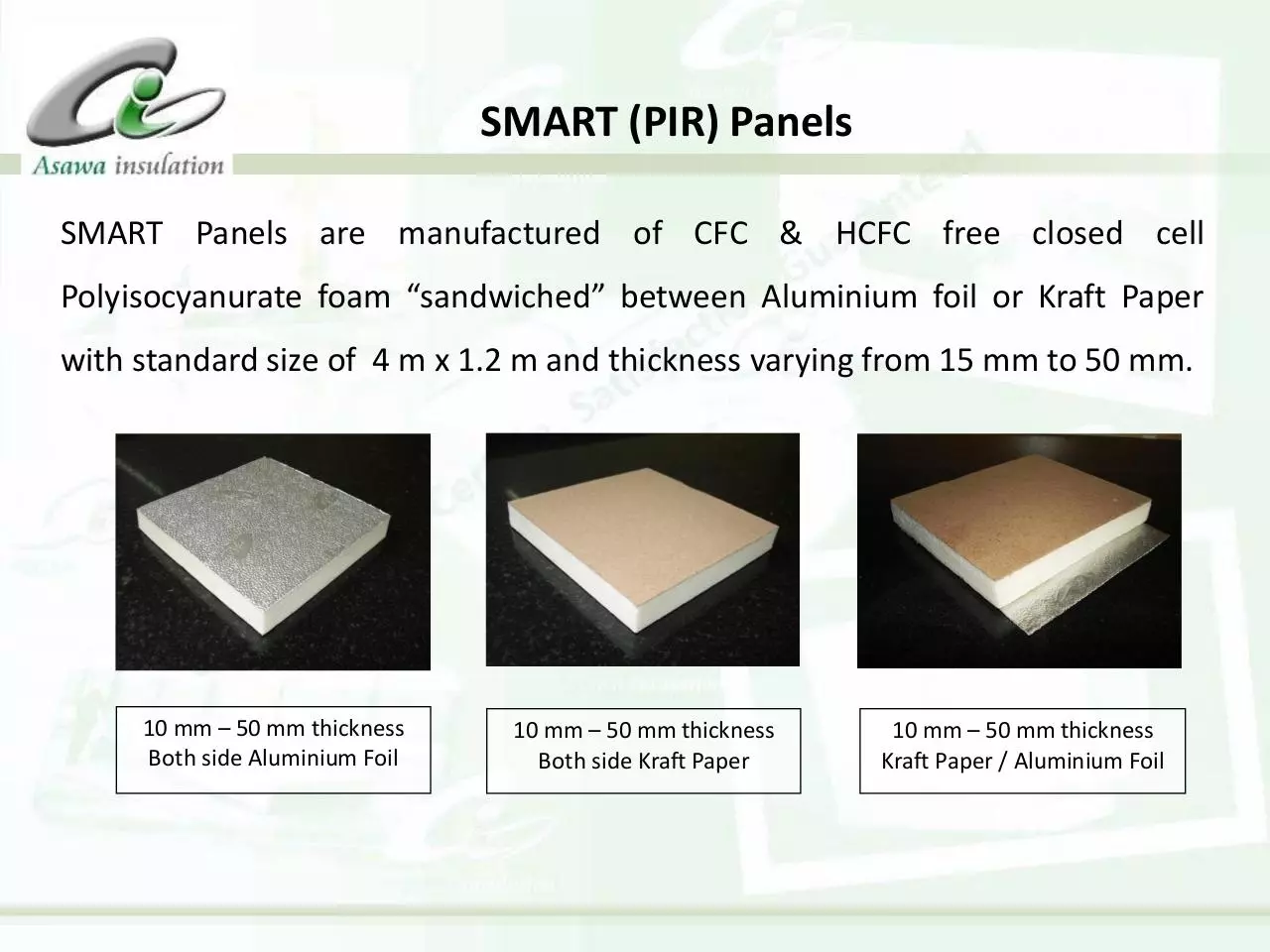

SMART Panels are manufactured of CFC & HCFC free closed cell

Polyisocyanurate foam “sandwiched” between Aluminium foil or Kraft Paper

with standard size of 4 m x 1.2 m and thickness varying from 15 mm to 50 mm.

10 mm – 50 mm thickness

Both side Aluminium Foil

10 mm – 50 mm thickness

Both side Kraft Paper

10 mm – 50 mm thickness

Kraft Paper / Aluminium Foil

SMART (PIR) Panels (Contd..)

SMART Panels are one of the best replacements of:-

• GI Ducts with Nitrile / Glasswool Insulation for HVAC Ducting System.

• Thermocol / Glasswool / Nitrile / Phenotharum for Underdeck & Overdeck

Insulation.

• Calcium Silicate tiles used for False Ceiling.

Applications

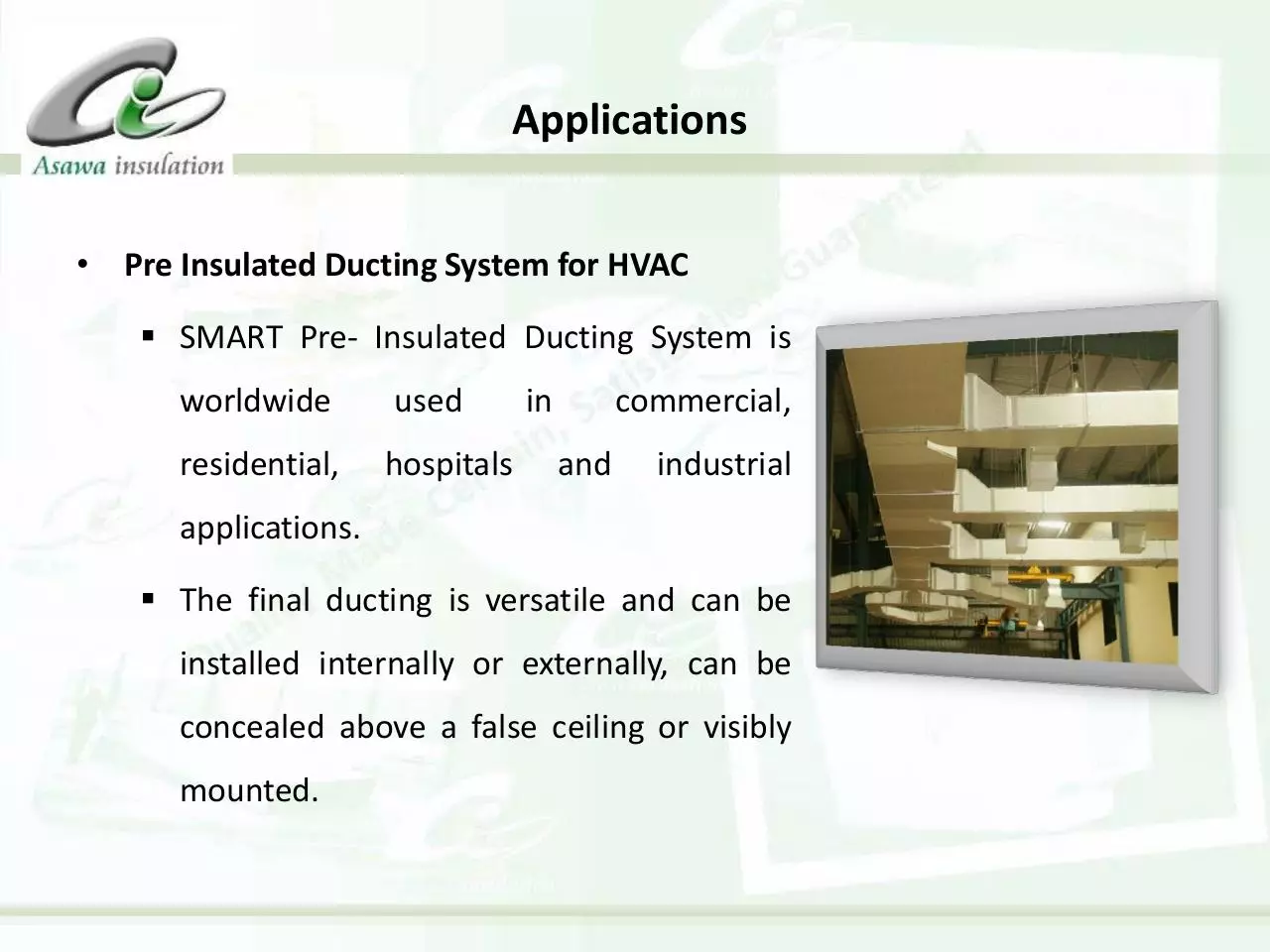

• Pre Insulated Ducting System for HVAC

SMART Pre- Insulated Ducting System is

worldwide

used

residential,

hospitals

in

commercial,

and

industrial

applications.

The final ducting is versatile and can be

installed internally or externally, can be

concealed above a false ceiling or visibly

mounted.

Applications (contd..)

• Wall Insulation

SMART Panels easily sticks to any surface and

there are no chances of creating any thermal or

cold bridges. We offer two variants for this

application.

Aluminium Foil / Aluminium Foil

Aluminium Foil / Paper

•

Floor Insulation / Roof Insulation

SMART Panels are applied seamlessly on the underside of the floor to prevent

heat transfer. PIR foam seamlessly seals the floor in contrast to the other

systems.

Applications (contd..)

• Underdeck Insulation / Overdeck Insulation

SMART Panels are applied to the surface of the

roof to prevent heat transfer. Thickness of the

panels varies from 15 to 50 mm. Variants available

under this application are

Aluminium Foil / Aluminium Foil

Aluminium Foil / Paper

Paper / Paper

Applications

• False Ceiling

SMART Panels are used as false ceiling to prevent

heat and noise transfer as it has better Insulation

and acoustic property as compared to calcium

silicate tiles. We offer two variants under this

application.

Aluminium Foil / Aluminium Foil

Paper / Paper

Advantages of SMART Panels

•

Environmentally Friendly –CFC & HCFC Free

•

Energy Saving: Up to 20% Annually

•

Low “U” Value

•

Moisture Resistance

•

Resistance to Fungus Growth

•

Uniform Insulation Density

•

Clean Air – Contains No Microfibre

Advantages of SMART Panels (Contd..)

•

Excellent Dimensional Stability

•

Damps Maximum noise

•

Cleanable and Hygienic

•

Retrofitting new ducts to an existing home

•

Light Weight Structure for New Buildings

•

Easy to Install - needs only duct layout details

•

Ducting addition to an existing establishment

Advantages of SMART Panels (Contd..)

• No Limits on Size of Ducting

• Space saving – Flush fitting installation

Advantages of SMART Panels

• Aesthetically beautiful

• Installed by fully factory trained

fabricators

SMART Panels v/s GI Ducting System with Glasswool

Description

SMART Panel Ducting System

GI. Ducting System with Glasswool

Insulation

Uniform, Self Insulated

Insulation is not uniform and

needed additionally.

Noise

PIR Panels ensure excellent sound Additional acoustic Insulation is

proofing & acoustic performance.

required to reduce noise.

Leakage

Fabrication

methodology

and Higher chances of air leakage

joinery system lead to negligible air because of contraction and

leakage.

expansion over a period of time.

Thermal

0.021W/m.K

Conductivity

0.028-0.036 W/m.K

SMART Panels v/s GI Ducting System with Glasswool

Description

SMART Panel Ducting System

Energy

Electricity saving upto 20% due to

minimal air leakage and better Higher electricity costs.

Thermal Conductivity of Insulation.

Corrosion

No Corrosion

Space

Less space is required as duct can More space is required for fixing

be insulated closer to ceiling.

Insulation & cladding.

No maintenance and very easy to

Repair and repair if physical damage occurs, no

Maintenance need to replace the entire system,

only damaged part is repaired.

GI. Ducting System with Glasswool

Corrosion due to humidity

Requires periodic maintenance and

if damage occurs the complete

section of duct needs to be

replaced.

SMART Panels v/s GI Ducting System with Glasswool

Description

SMART Panel Ducting System

GI. Ducting System with Glasswool

Site Fabrication

Possible. Six times faster.

Possible but time consuming.

Appearance

Nice and more appealing.

Less appealing.

Cost

Comparable

-

Negligible water absorption

Water absorption exists at a very

Water Absorption (0.03% after immersion in

higher rate.

water for 24 hrs).

Material Handling

Not Required.

Precautions

Required as Glasswool causes skin

irritation and affects the respiratory

system.

Product Life

Less due to corrosion

More

SMART (PIR) Panels v/s Polyurethane (PU)

Description

SMART (PIR) Panels

Polyurethane (PU)

Insulation Material Type Thermostat

Thermoplastic

Effect of Ultraviolet Light No affect.

UV Light degrades PU.

PIR is not affected by

Effect of Construction solvents in adhesives,

Material

paints,

strain,

water

repellent & preservatives.

PU can be attacked with many

solvents in adhesives, paints,

strain, water repellent and

preservatives.

Thermal Conductivity

0.021 W/m.K

0.024 W/m.K

Density

More than 40 Kg/m³

More than 28 Kg/m³

Water Absorption

0.00 perms

2.23 perms

SMART (PIR) Panels v/s (PU) Polyurethane (Contd..)

Description

Effect of

Temperature

SMART (PIR) Panels

Polyurethane (PU)

PIR will not become supple or melt

PU will start softening & dripping

away at increased temperatures at

at temperature above 165°F and

above 200°F - 300°F without losing

melts above 200°F.

its rigidity.

Water Vapour

No

Transmission

Water will penetrate and

condense the cells thus reducing

Insulation Value.

Fire Propagation BS 476, Part 6, Class 0, with better

BS 476, Part 6, Class 0

Properties

Fire retardant properties.

Apparent

Closed Cell

More than 95%

More than 95%

Thermal

Performance

More R Value per inch

Less R Value per inch

SMART Panels v/s Nitrile Rubber

Description

SMART (PIR) Panels

Nitrile Rubber

Insulation Property

Higher

Lower

Thickness to achieve similar

properties

20 mm

38 mm

Density

48 Kg/m³

30 Kg/m³

Thermal Conductivity

0.021 W/m.K

0.032 W/m.K

Water Vapour Transmission

No

Yes

Water Absorption

0.03%

0.90%

Acoustic Property

Higher

Lower

SMART Panels v/s Nitrile Rubber (Contd..)

Description

SMART (PIR) Panels

Nitrile Rubber

Surface Facing

Both side Aluminium foil.

No facing.

Apparent closed cell

More than 95%.

Upto 90%.

Flame Spread

Less

More

Product Life

More

Less

Performance Reduction

Not seen even in the Cracks are seen after 2 to

longer run.

3 years.

Fire Propagation Properties

BS 476, Part 6, Class 0.

BS 476, Part 6, Class 0.

SMART Panels v/s Expanded or Extruded

Polystyrene (Underdeck / Overdeck Insulation)

Properties

SMART (PIR) Panels

Expanded / Extruded

Polystyrene (XPS / EPS)

Width

10, 15, 20, 25, 30, 35, 40, 45, 50

25, 50, 75, 100 mm

mm

1200 mm

1000 mm

Density

More than 45 Kg/m3

Surface

With Aluminium Foil or Kraft

Nil

Paper

Thickness

Less than 35 Kg/m3

Fire Retardant Rating BS 476, Part 6, Class 0

Class 1

Thermal Conductivity 0.021 W/m.K at 35°C

0.032 W/m.K at 25°C

Moisture Content

0.03%

More than 1%

Service Temperature

-40°C to 150°C

-10°C to 150° C

SMART (PIR) Panels v/s Calcium Silicate

tiles (False Ceiling)

Properties

SMART (PIR) Panels

Calcium Silicate Tiles

Thickness

Maximum upto 50 mm

Maximum upto 25 mm

Length

Upto 4000 mm

610, 1220, 1830 and 2440 mm

Width

600, 1200 mm

600, 1200 mm

Density

48 Kg/m³

More than 800 kg/m³

Surface

With Aluminium Foil or Kraft

Nil

Paper

Fire Retardant Rating

Class 0

Class 0

Surface Spread of Flame

Class 1

Class 1

Effect of Condensation

Not affected

Patches occurs on tiles

Underdeck Insulation

Not required

Required

SMART (PIR) Panels v/s Calcium silicate

tiles (False Ceiling)

Properties

SMART (PIR) Panels

Calcium Silicate Tiles

Fire Propagation Index

I > 7.8 R

I < 4.0

Thermal Conductivity

0.021 W/m.K

0.15 W/m.K

Thermal Resistance

0.90 m2 K/W for 20 mm

0.04 - 0.08 m2K/W for 6 -25 mm

Moisture Content

0.03% by Volume

Upto 15% by volume

Length change in after

Not affected

Water Absorption

0.15%

Weight

Very light weight

Four times heavier

Service Temperature

-40°C to 150°C

0°C to 150°C

Not affected

Fading and discoloration

Visual Appearance

Contact with Water

on

CERTIFICATIONS

Standard Followed

Certification Body /

Laboratory

Classification &

Results

ISO

9001:2008

URS

ISO Certified

CE

89/106/EEC

ECA

CE Certified

Fire Propagation

Index

BS 476 Part 6

Description

Ignitability Test

Surface Spread

of Flame

BS 476 Part 5 / Part 12

BS 476 Part 7

Certification of Product BS 476 Part 6 & Part 7

• Warringtonfire, UK

• CBRI Roorkee, India

• Warringtonfire, UK

• CBRI Roorkee, India

• Warringtonfire, UK

• CBRI Roorkee, India

Warringtonfire, UK

Class “O”

Certified

Certified

Certified

CERTIFICATIONS (Contd..)

Description

Standard Followed

Certification Body

/ Laboratory

Warringtonfire,

Canada

Classification &

Results

Flame Spread Index

ASTM E-84

Smoke Development

Index

ASTM E-84

Warringtonfire,

Canada

Certified

Norms of IGBC

Indian Green

Building Council

Approved

Thermal and Humid

Aging

ASTM D-2126:09

Dubai Central

Laboratory

No major Deviation

Apparent Density with

both side Aluminium Foil

ASTM D 1622:03

Dubai Central

Laboratory

45 kg/m³

Green Building Product

Certified

CERTIFICATIONS

Description

Certification Body /

Standard Followed

Laboratory

Classification &

Results

ASTM C:518:2010

Dubai Central

Laboratory

0.021 W/(m.K)

BS EN 823:95

Dubai Central

Laboratory

21 mm

ASTM C 209:1998

Dubai Central

Laboratory

0.03%

Water Vapour transmission

ASTM E 96 - 00

Dubai Central

Laboratory

0.00 perms

Flexural Strength of

thermal Insulation

ASTM C 203-05a

Dubai Central

Laboratory

Certified

ASTM C 1304-08

Dubai Central

Laboratory

No Odor Emission

Thermal Conductivity

Thickness of Thermal

Insulation

Water Absorption Test

Odor Emission

CERTIFICATIONS

Description

Green Building Product

Eco Warranty

Sound Absorbing Material

Sound Transmission Loss

Oxygen Index

Certification Body /

Standard Followed

Laboratory

As per ECBC code Indian Green Building

and IGBC Norms

Council

Classification &

Results

Approved

Management

Standard

ICL

Awarded

IS: 8225 - 1987

National Physical

Laboratory

NRC = 0.3

IS: 9901, Part 3

DIN 52210, Part 4

ISO: 140, Part 3

National Physical

Laboratory

STC = 0.32

Bharat Test House

<29.0

ASTM D 2863

CERTIFICATIONS

Description

Bacteria Resistance Test

Fungus Resistance Test

Mold Growth

Heavy Metals

(Cd, Hg, Pb, Cr)

Overall Migration Test

Standard Followed

Certification Body /

Laboratory

Classification &

Results

ASTM G 22

ASTM G 21

IS 3144:1992

Bharat Test House

No Growth Found

AAS

Bharat Test House

Under Material

Regulation

IS 9845

Bharat Test House

1.1

Certifications (Contd..)

ISO 9001:2008

Certifications (Contd..)

CE CERTIFIED

Certification (Contd..)

Class O according to BS 476 part

6 &7

Summary of WARRES No’s

306981 & 306982 Including

Opinion Of Compliance With

The Requirements For A Class 0

Surface

As Defined In The

Paragraph A13 (b) of Approved

Documents ‘B’ Fire Safety, To

the building Regulations 2000

The Professionals in Fire Safety

Major Clientele (Jan 2012 onwards…)

Major Clientele (Jan 2012 onwards…)

Reliance Hyper Mall

SKH, Maruti Pune

JSW, Alibaugh

Reliance Retail, Pune

E Cube, Raigadh

Motilal Oswal Tower, Mumbai

Contact Us

Asawa Insulation Pvt. Ltd.

Registered Office

: H-2, 2:1, Panchdeep CHS, Sector-29,

Vashi, Navi Mumbai-400703, India

Tel No.

: +91 22 27665199

Fax

: +91 22 27665199

Mobile

: +91 9819192929 / 9619193939

: info@asawainsulation.com

Website : www.asawainsulation.com

Download Asawa Insulation - COMPANY PROFILE

Asawa Insulation - COMPANY PROFILE.pdf (PDF, 3.86 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000095241.