Spotty V1 Manual (PDF)

File information

This PDF 1.4 document has been generated by Writer / OpenOffice.org 3.4.1, and has been sent on pdf-archive.com on 07/05/2013 at 21:21, from IP address 89.164.x.x.

The current document download page has been viewed 3687 times.

File size: 7.68 MB (8 pages).

Privacy: public file

File preview

Spotty v1

User manual

Spotty v.1

Wire welding device

by

HELEX

&

VonMacher

User Manual

Made in Croatia

1 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Device description

Picture 1

Picture 1: Basic layout

Technical specifications

Power supply:

9V 6LR61 Alkaline or NiCd/NiMh rechargeable block any DC

power supply up to 24 V

Output voltage:

up to 37 V DC, adjustable

Charging time:

up to 3 sec (depending on output voltage setting)

Battery life time:

up to 10 hours (device ON) over 500 charging (spot welding)

Weight:

152 gr (w/o battery)

Dimensions (L×W×H):

130×68×25 (53) mm

Made in Croatia

2 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Special features & protections

Reverse polarity protection - device is operational no matter of power supply polarity

turnover.

Output short circuit protection – if output terminals are shorted while charging button is

pressed, automatic protection feature will cut output current to minimum.

WARNING! Shorting the output terminals will never harm the device, but battery life time

significantly decrease!

Charging voltage regulation – charging voltage can be controlled in two ways:

● Via regulator knob (2) steplessly. This will determine the maximum charging voltage.

● Via charging button (3). Charging time of cca 3 seconds allows you to monitor charging

voltage and terminate it at any desired voltage lower than maximal

determined at regulator knob (2).

Precision welding support – provides high precision wires aligning and welding even in low

visibility conditions. Reduces number of faulty welding attempts to minimum.

Safety precautions – since Spotty v1 uses a low voltage welding technology (same as all

spot welders in car body shops for instance), there is absolutely no possible danger of

electric shock or any injuries what so ever.

Working principles

Spot welding basics

To create a welding spot it is necessary to provide a high energy boost in a very short

period of time with losses as small as possible. Those losses are mainly electrical

resistance created by bad contacts and if not eliminated they will significantly decrease

welding quality.

Further more, while welding, it is necessary to have almost the same condition for every

welded spot, to be sure that result will always be satisfactory.

Electrical losses by means of resistance are mainly created on connecting points, but also

at the welding spot. Therefore both wires (NR and R) must be well clamped (R wire as

shortest as possible to reduce its internal impedance), and welding points on wires must

be clean of any residual dirt (greasiness, patina, previous welding attempts coating).

Made in Croatia

3 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

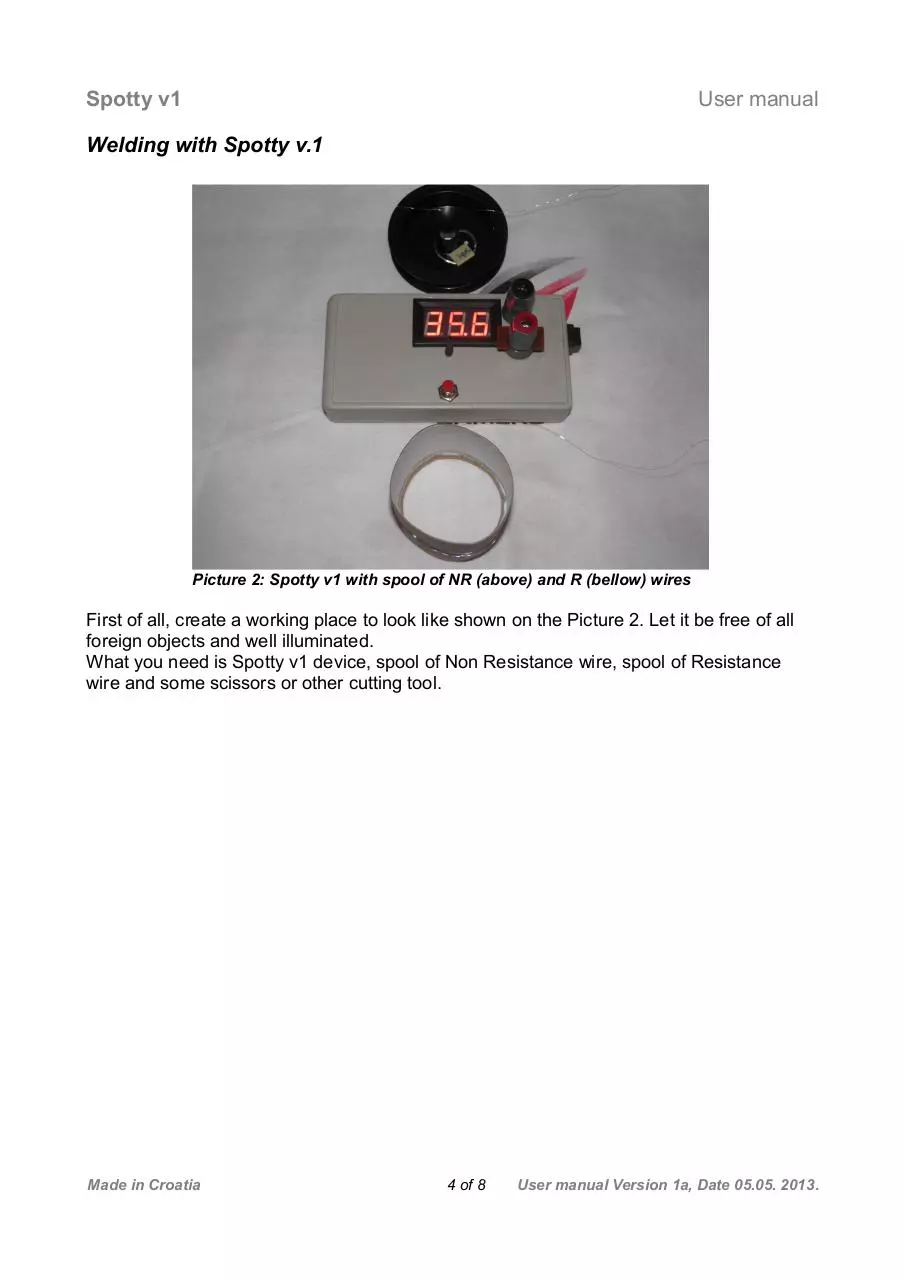

Welding with Spotty v.1

Picture 2: Spotty v1 with spool of NR (above) and R (bellow) wires

First of all, create a working place to look like shown on the Picture 2. Let it be free of all

foreign objects and well illuminated.

What you need is Spotty v1 device, spool of Non Resistance wire, spool of Resistance

wire and some scissors or other cutting tool.

Made in Croatia

4 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Let's create a good connections

Please note end terminal holes. It is

mandatory to protrude wires through those

holes and clamp it with upper nut.

Note: NR wire can be wrapped 1 round

around the black post screw and clamped that

way.

That will ensure the best possible electrical

connection and reduce losses to minimum..

Picture 3: End terminal mid holes

Resistance wire must be clamped on RED

post. To do that, please unscrew red plastic

nut, protrude wire through the mid hole

(Picture 3) and clamp it with red plastic nut

(fingers only!).

Let wire lies on support like shown on Picture

3. Straight ahead, or even 45o toward black

post could be better, depends on personal

customization.

Note: Up to 5 mm should be good enough. It

is mandatory to have R wire protrusion as

short as possible, so its internal impedance

will have less influence to welding result.

Picture 4: R wire clamping and aligning

Picture 5: NR wire clamping

Made in Croatia

There are two good ways of clamping the NR

wire.

1. Protrude it through the mid post hole and

clamp it.

2. Wrap it around the black post screw and

clamp it that way.

Both ways will provide best possible electrical

connection and allow you to easily prolong the

wire when needed. Just unscrew a bit and

pull.

Wire should protrude long enough to be easily

guided by fingers toward red post support.

Approx. length 10 cm.

Note: Please don't prolong NR wire to much

since its internal impedance can decrease

welding result!

5 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Welding procedure

Now it's time to charge the device and weld.

1. Turn the device ON (switch 6)

2. Adjust voltage if necessary (regulating

knob 2)

3. Press charging button (3) and watch

voltage increasing. It will slow down and

finally stop at preset voltage.

4. Release the charging button (3)

5. Slide NR wire over the support surface,

align it carefully to R wire and make a

connection. Let wires overlap for at least 1

– 2 mm. Connection will create moderate

spark and some noise. It is normal, there is Picture 6: Aligning and welding procedure

nothing to worry about.

(please note the wires overlap)

Now you can unscrew the red post nut and

pull the R wire to the desired length

(resistance). At this point you can attach the

ohmmeter to output posts to measure future

setup resistance. Just remember to clamp red

post nut.

You should get something similar as shown

on the Picture 7.

Illustration 7: First welding spot is made.

Cut the NR wire at desired length. Unscrew

black post nut and pull NR wire out to get

length of previously mentioned aprox. 10 cm

and tighten it again.

Now fold R wire (with already welded one

side) to the left (opposite to black post) and

align it to support. Please refer to the Picture

8.

Now you have other side of R wire ready for

welding and inline with NR wire.

Picture 8: Folding R wire enables inline

welding

Made in Croatia

6 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Using the same method explained before,

weld NR wire to the other side of the R wire.

Please refer to the Picture 9.

Picture 9: Welding the other side

After welding is finished, you will get

assembled wires like shown on Picture 10.

Use scissors or cutter pliers to cut R wire as

closest as possible to the welding spot and

NR wire to desired length.

Note: After some practice you will be able to

adjust Spotty to burn out the rest of R wire, so

it will fall off the red post automatically,

creating at the same time almost perfect

welding spot.

Picture 10: After welding the other side of

R wire

Note: It is possible to use another method for welding the other side of R wire. Instead of

folding it (refer to Picture 7), you can cut the R wire to desired length (resistance), unscrew

the red post nut, remove spooled R wire and protrude the other side of R wire in process.

Clamp it and align it in exactly the same way as you did in first attempt and proceed with

welding procedure as explained before (refer to Picture 4 – 6). The result will be the same,

but it will last a bit longer to prepare.

Made in Croatia

7 of 8

User manual Version 1a, Date 05.05. 2013.

Spotty v1

User manual

Care and maintenance

Spotty v1 demands almost no maintenance at all.

Nevertheless, some things you should keep in mind.

Battery has to be changed when adjusted voltage is not reachable.

Take out worn battery carefully. Don't ever pull battery connector for wires, you will

damage it.

If device is not to be used for a prolonged time, disconnect the battery.

Keep the device in a dry place. It is not intended for outdoor usage.

Never leave the device switched on if not in use. It will flat out the battery.

Picture 11: Battery compartment

Troubleshooting

Desired voltage is not adjustable

• output voltage can be adjusted to max. 37 V. If this or every lower value is not

reachable, please replace the battery.

Spot welding quality is poor

• Please check all electrical connections as described in this manual.

• Please check the wires on its ends (welding points) for any residual dirt.

• Please check the charging voltage. Maybe is necessary to rise a welding voltage.

For instance, changing the wire type will probably ask for welding parameters

change.

• Be sure that R wire don't protrudes to much from red post. You should perform

welding approx. 5 mm away from post on the support.

If your first attempt is not satisfactory, just charge and try again. Maybe it will be necessary

to cut few millimeters of wire ends to have a nice clean surface.

Please don't press the charging button while wires are still connected. It will not damage

the device, but will drain the battery with no welding effect at all.

Note: It is mandatory to make a few tests and to have some practice. After few welded

spots, number of faulty welding will be insignificant.

Made in Croatia

8 of 8

User manual Version 1a, Date 05.05. 2013.

Download Spotty V1 Manual

Spotty_V1_Manual.pdf (PDF, 7.68 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000103647.