VME Brochure 2015 (PDF)

File information

This PDF 1.4 document has been generated by Adobe InDesign CS6 (Macintosh) / Adobe PDF Library 10.0.1, and has been sent on pdf-archive.com on 08/04/2015 at 12:30, from IP address 217.41.x.x.

The current document download page has been viewed 1104 times.

File size: 9.25 MB (114 pages).

Privacy: public file

File preview

LOADS

better

VEHICLE MOUNTED LIFTING EQUIPMENT

HSE safety statistics…

point to the benefits

of lifting equipment.

The latest statistics from the HSE expose yet again the need to avoid

manual handling and give more credence to calls for wider use

of vehicle mounted cranes and other load handling devices.

The figures show that across all industries 31% of all fatal, serious

and over-three-day injuries during the last reporting year were

related to manual handling. This represents 37,000 people whose

lives have been directly affected.

In the motor transport sector the story is even worse, with 38% of all

reportable injuries related to manual handling. So while handling related

injuries are significant in all industries the road transport sector has even

more work to do to improve its safety record. The simplest and most effective

way to reduce the risk of this type of injury is to eliminate the need for manual

handling by changing the processes involved and providing employees with

suitable load handling equipment.

CONTENTS

PH Cranes

SwingLift Cranes

Winches

Loading Platforms

Accessories, Planned Maintenance & Glossary

In the road transport industry a further 35% of all reportable injuries were

caused by slips, trips and falls from height. This includes falls from delivery

and service vehicles. Incidents like this can be avoided by removing the need

to approach or climb on a vehicle. Provision of appropriate load handling

equipment is one possible solution.

While there may be a temptation to think that injuries are not going to happen

there is another way of looking at the HSE figures: an accident or injury

caused by manual handling or a slip, trip or fall is much more likely

than one caused by fire or electric shock which have historically been taken

far more seriously.

Often the simplest way to reduce the risk of an accident and resulting injury

is to remove the potential cause. Providing employees with a crane on their

vehicles is a good place to start. Manufacturers such as Penny Hydraulics

continue to play their part by adding new features that promote safety

and make it easier for operators to specify and install their products.

Hydraulic extension

PH Range

PH50

Standard manual extension

PH150

C

980

1700

2470

kg

500

300

200

3010

mm

980

1700

2470

kg

500

300

200

B

PH150

50.2M

980

1700

kg mm 500 980

kg

150.3

2470

300 1700200 2470

500

300

150.2

mm

980

1700

2470

kg

500

300

200

PH110

1050

980

990

500

1930

2800

1700

2470

540

370

300

200

3730

1050

1930

2800

3730

4500

kg

990

540

370

250

200

B

110.1

110.3

C

5000

kg

1300

990

700

700

480

480

350

B

350

250

C

250

*

mm

*

PH180

1160

*

2080

3010

1230 990 670 830 470 570

990

670

470

4000

1050

1930

2800

3730

4500

mm

1100

1980

2850

3730

4500

kg

990

540

370

250

200

kg

990

540

370

250

200

5000

350 420 250 280

C

350

250

3060

4000

5000

kg

1450

990

800

800

550

550

420

420

280

280

mm

1160

2080

3010

4000

5000

kg

1500

990

830

830

570

570

420

420

280

280

*

B

C

540

370

250

200

kg

*

540

370

250

200

PH230

680 420

680 420

500280

500280

350

350

Standard manual extension

230.3

2150

990

1180

990

810

810

600

400

B

600

400

mm

1400

1260

2260

kg

1870

* 2030 990 1130

990

990

2600

3260

1000

990780

780

3800

4200

680

600

680

600

mm

1460

2660

3860

5000

6000

kg

1770

990

950

950

650

650

500

500

350

350

*

*

*

*

C

1260

2260

3260

4200

5200

kg

1800

990

950

950

650

650

500

500

350

350

mm

1200

kg

B/C/D

1800

*

990

2200

3200

4200

1000

680

500

350

Optional manual

extension

990

680

500

350

330.4

500

B

500

2300

6000

350

350

C

D

4360

5360

6360

6000 550

550

350

C

350

420

420

D

mm

1360

2360

3360

4360

5360

6360

kg

2350

990

1350

990

950

950

700

700

550

550

420

420

*

mm

*

“D” version

5000

680

680

5000700

700

500

500

1300

2300

3300

2500

1400

1000

mm990 1430 990 2430 990 3430

kg

330.3

*

3800

1000

990

3300

kg

5200

2600

1870

990

1300

C

5000

6000

5200

500

350

400

500

350

C

400

1400

mm

330.4

5200

mm kg1460 2500 2660 1400 38601000

* 1770 990 950 990 650 990

kg

990

950

650

*

330.2

mm

*

230.2

Hydraulic extension

kg1450 1800 800 1000 550

* 990 990 800 990 550

230.3

990

kg

PH330

990

kg

4200

330.3

kg

4500

3200

270L.3

mm mm

1210 12002140 22003060 3200 4000 4200

5000 5200

3730

2200

330.2

4500

2850

1200

kg

3730

1980

400

400

PH330

mm

2140

2800

1100

5200

600

600

270L.2

1930

mm

4200

780

780

PH270L

1050

C

3260

1130

990

kg

mm

110.3

2260

mm

270L.2

270.3

230.2

180.3

110.2

1260

2030

990

PH270L

270L.3

1210

PH230

C

kg

mm

mm

*

180.2

C

4000

4200

5200

“D” version

600

400

600

400

mm

*

270.2

mm kg 12101500 2140 830 3060 570 4000 420 5000 280

mm

B

3010

5000

kg

mm

PH270

C

2080

4000

180.3

PH110

250

250

3010

200

110.2

5000

350

350

2080

4500

250

4000

480

480

1160

150.3

mm

mm

kg

kg

3010

700

700

mm

PH180

180.2

110.1

50.2ERS

2080

kg mm13001210 700 2140 480 3060 350 4000 250 5000

* kg 990 1230 700 670 480 470 350 350 250 250

990

670

470

350

250

*

200

50.2H

1160

1300

990

1160

*

270.3

kg

mm

mm

1200

2200

3200

Optional manual extension

kg

2150

1180

810

990

990

810

*

C

mm

*

150.1

mm

4000

5000

Standard manual extension

350

250

350

250

480

480

150.2

PH50

C

270.2

mm

1160

2080

Hydraulic extension

kg

1300

700

990

700

*

50.2H

“D” version

B

150.1

mm

*

PH270

B

50.2M

50.2ERS

Optional manual extension

*

2200

990

1300

990

D

4360

5360

700

700 4430

550

420

550 5360 420 6360

900

900

700

700

6360

550

550

420

420

mm

1360

2360

3360

4360

5360

6360

kg

2350

990

1350

990

950

950

700

700

550

550

420

420

*

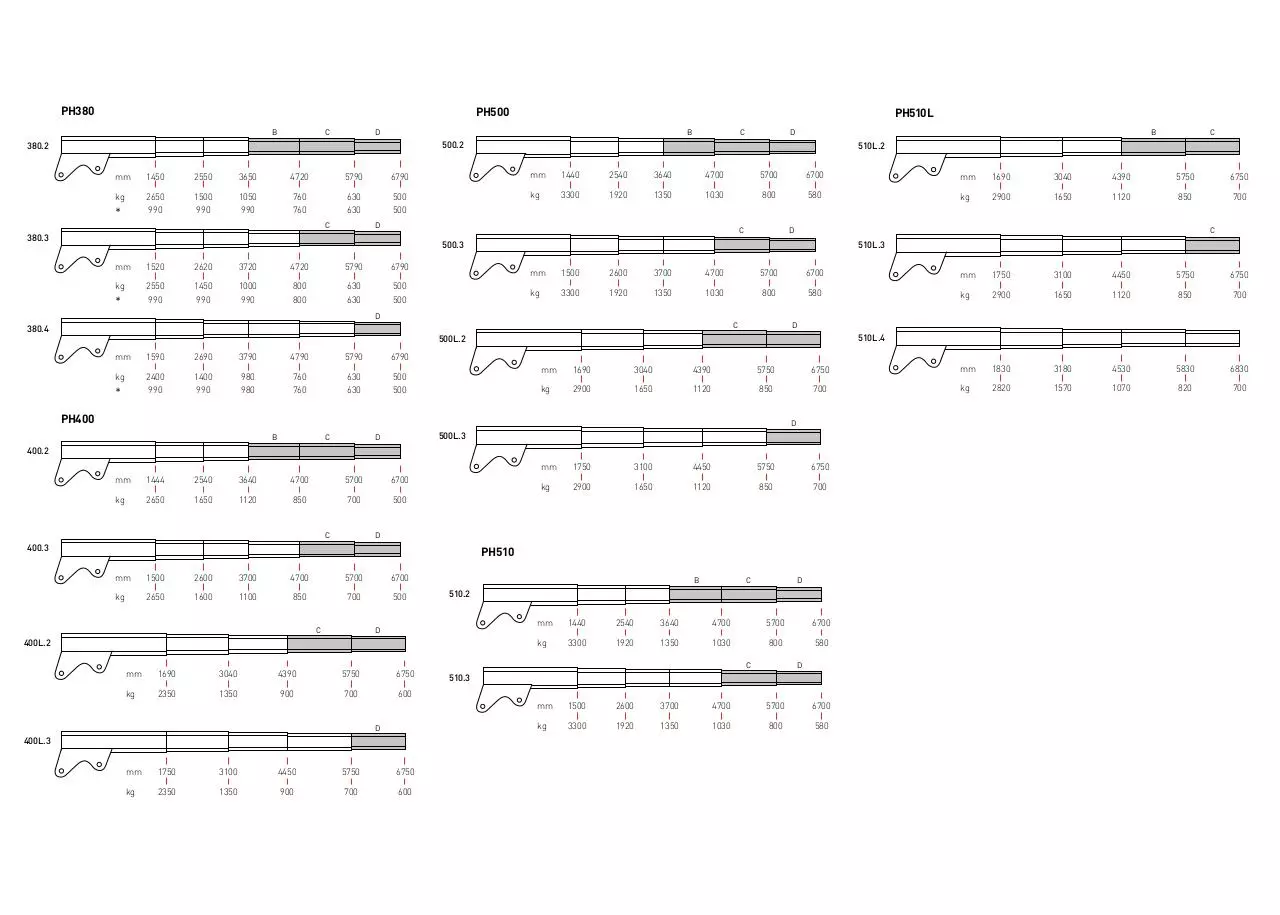

PH380

PH500

B

C

PH510L

D

B

C

B

D

500.2

380.2

C

510L.2

mm

1450

2550

3650

4720

5790

6790

mm

1440

2540

3640

4700

5700

6700

mm

1690

3040

4390

5750

6750

kg

2650

990

1500

990

1050

990

760

760

630

630

500

500

kg

3300

1920

1350

1030

800

580

kg

2900

1650

1120

850

700

*

C

D

C

380.3

D

C

510L.3

500.3

mm

1520

2620

3720

4720

5790

6790

kg

2550

990

1450

990

1000

990

800

800

630

630

500

500

*

mm

1500

2600

3700

4700

5700

6700

mm

1750

3100

4450

5750

6750

kg

3300

1920

1350

1030

800

580

kg

2900

1650

1120

850

700

D

C

380.4

D

510L.4

500L.2

mm

1590

2690

3790

4790

5790

6790

kg

2400

990

1400

990

980

980

760

760

630

630

500

500

*

mm

1690

3040

4390

5750

6750

mm

1830

3180

4530

5830

6830

kg

2900

1650

1120

850

700

kg

2820

1570

1070

820

700

PH400

D

B

C

500L.3

D

400.2

mm

1444

2540

3640

4700

5700

6700

kg

2650

1650

1120

850

700

500

C

mm

1750

3100

4450

5750

6750

kg

2900

1650

1120

850

700

D

400.3

PH510

mm

1500

2600

3700

4700

5700

6700

kg

2650

1600

1100

850

700

500

C

B

D

400L.2

mm

1690

3040

4390

5750

6750

kg

2350

1350

900

700

600

D

400L.3

mm

1750

3100

4450

5750

6750

kg

2350

1350

900

700

600

C

D

510.2

mm

1440

2540

3640

4700

kg

3300

1920

1350

1030

5700

6700

800

C

580

D

510.3

mm

1500

2600

3700

4700

5700

6700

kg

3300

1920

1350

1030

800

580

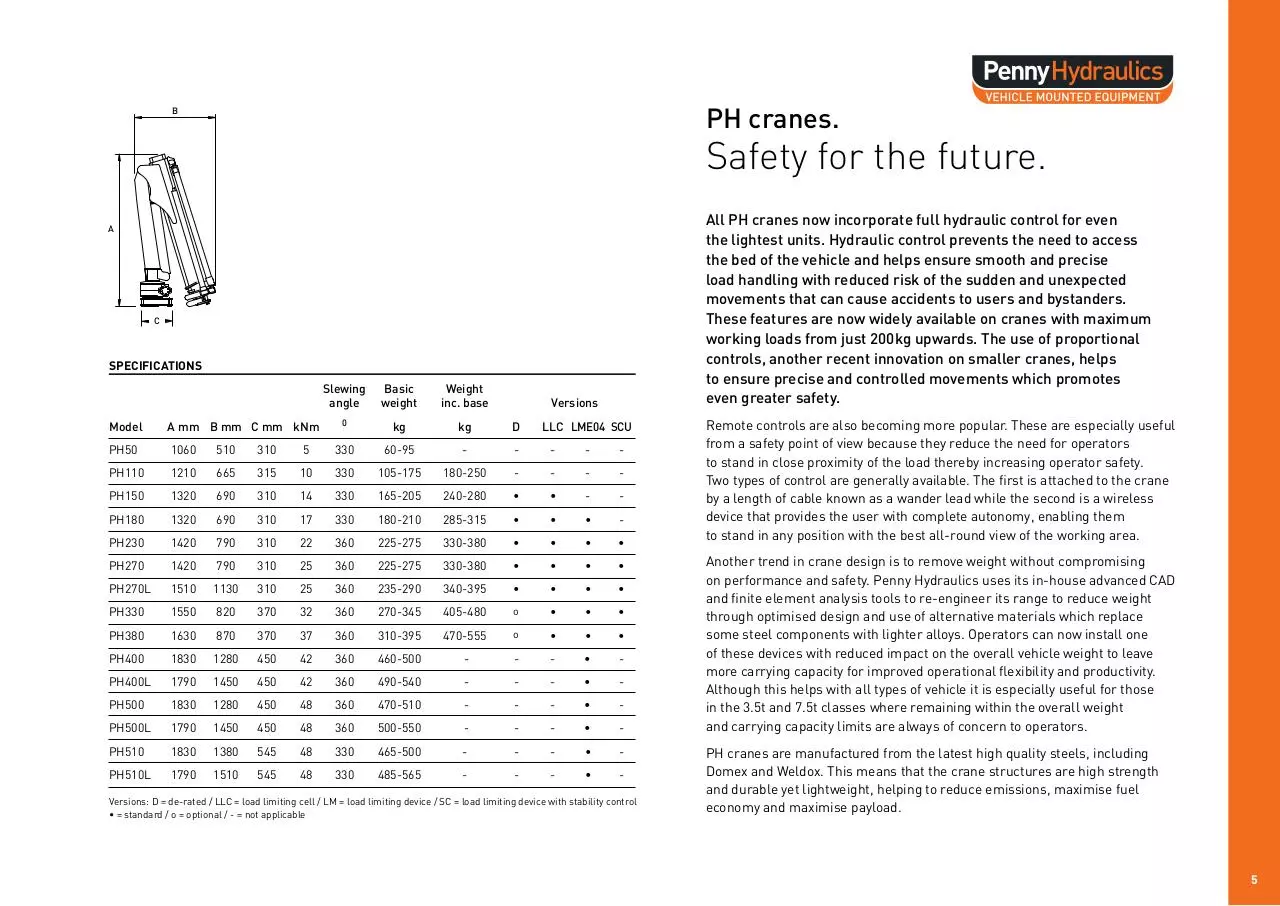

PH cranes.

B

Safety for the future.

All PH cranes now incorporate full hydraulic control for even

the lightest units. Hydraulic control prevents the need to access

the bed of the vehicle and helps ensure smooth and precise

load handling with reduced risk of the sudden and unexpected

movements that can cause accidents to users and bystanders.

These features are now widely available on cranes with maximum

working loads from just 200kg upwards. The use of proportional

controls, another recent innovation on smaller cranes, helps

to ensure precise and controlled movements which promotes

even greater safety.

A

C

SPECIFICATIONS

Slewing Basic Weight

angle

weight

inc. base

Model

A mm B mm C mm kNm

PH50

1060

510

310

5

0

330

kg

60-95

kg

-

Versions

D LLC

LME04 SCU

-

-

-

-

PH110 1210 665 315 10 330 105-175 180-250 - - - PH150 1320 690 310 14 330 165-205 240-280 • • - PH180 1320 690 310 17 330 180-210 285-315 • • • PH230 1420 790 310 22 360 225-275 330-380 • • • •

PH270 1420 790 310 25 360 225-275 330-380 • • • •

PH270L 1510 1130 310 25 360 235-290 340-395 •

• • •

PH330 1550 820 370 32 360 270-345 405-480 o • • •

PH380 1630 870 370 37 360 310-395 470-555 o • • •

PH400

1830

1280

450

42

360

460-500

-

-

-

•

-

PH400L

1790

1450

450

42

360

490-540

-

-

-

•

-

PH500

1830

1280

450

48

360

470-510

-

-

-

•

-

PH500L

1790

1450

450

48

360

500-550

-

-

-

•

-

PH510 1830 1380 545 48 330 465-500

-

-

- • -

PH510L 1790 1510 545 48 330 485-565

-

-

- • -

Versions: D = de-rated / LLC = load limiting cell / LM = load limiting device / SC = load limiting device with stability control

• = standard / o = optional / - = not applicable

Remote controls are also becoming more popular. These are especially useful

from a safety point of view because they reduce the need for operators

to stand in close proximity of the load thereby increasing operator safety.

Two types of control are generally available. The first is attached to the crane

by a length of cable known as a wander lead while the second is a wireless

device that provides the user with complete autonomy, enabling them

to stand in any position with the best all-round view of the working area.

Another trend in crane design is to remove weight without compromising

on performance and safety. Penny Hydraulics uses its in-house advanced CAD

and finite element analysis tools to re-engineer its range to reduce weight

through optimised design and use of alternative materials which replace

some steel components with lighter alloys. Operators can now install one

of these devices with reduced impact on the overall vehicle weight to leave

more carrying capacity for improved operational flexibility and productivity.

Although this helps with all types of vehicle it is especially useful for those

in the 3.5t and 7.5t classes where remaining within the overall weight

and carrying capacity limits are always of concern to operators.

PH cranes are manufactured from the latest high quality steels, including

Domex and Weldox. This means that the crane structures are high strength

and durable yet lightweight, helping to reduce emissions, maximise fuel

economy and maximise payload.

5

PH50

Quick fastening kit

A small, lightweight, compact crane with a wide range of variations

to suit most applications including pick-ups, vans, ATVs and trailers.

FEATURES

OPTIONS

• Counter flange mounting plate

• Fitting kit

• Quick fastening kit - allows for fast

& easy deployment and removal of

the crane. Also allows one crane to be

mounted to multiple vehicles

• Stabiliser/outrigger pads

• Electro-hydraulic version with hydraulic

boom lift, extension & slew powered by simple

connection to a battery source

• Easy to assemble & demount

• Manual stabiliser leg kit

• Simple to operate

• Backward attachment kit - for van

applications to help centre the load

for ease of loading

• Manual version - with pump up boom,

pump operated slewing & boom extension

• Stabiliser leg extensions

• Marinised paint finish

3 function proportional control

7

PH50

Weights & measurements

All dimensions in millimetres; all weights to the nearest kilogram; E & OE

Standard manual extension

Hydraulic extension

50.2M

50.2H

50.2ERS

mm

980

1700

2470

mm

980

1700

2470

mm

980

1700

2470

kg

500

300

200

kg

500

300

200

kg

500

300

200

kg (without winch)

kg (with winch)

TECHNICAL DATA

PH50.2M PLH

74

85

Lifting capacity

PH50.2H PLH

83

94

PH50.2H ELH

81

92

Max. lifting height

from crane base

PH50.2M ERH

78

89

PH50.2H ERH

85

96

PH50.2 ERS

91

-

CRANE WEIGHTS

Max. working slope

5kNm

3400mm

4°

Max. working pressure

170bar

Electro-hydraulic power

unit supply voltage

12V/24V

Max. absorption

electro-hydraulic power unit

100A/50A

Hydraulic oil tank capacity

1.6l

Max. absorption

electrical winch

30A

ACCESSORIES WEIGHTS kg

Stabiliser kit

20

Counter flange

6

Quick fitting kit

20

Back load attachment kit

1.7

LOAD CHART PH50

LOAD CHART PH50 (with optional winch)

4

4

4

4

3

3

3

3

2

2

2

2

1

0

1

mm

980

mm 1700

980

2470

1700

2470

kg

500

kg

200

300

200

0 1

300

500

1 2

2 3

0

1

mm

0

3 0

1140

0 1

mm 1830

1140

1 2

2630

1830

1

2630

2 3

0

3

0

9

Download VME Brochure 2015

VME Brochure 2015.pdf (PDF, 9.25 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000219832.