AQS Beat Nov Dec 2015 (PDF)

File information

This PDF 1.7 document has been generated by Adobe InDesign CS6 (Windows) / 3-Heights(TM) PDF Optimization Shell 4.6.19.0 (http://www.pdf-tools.com), and has been sent on pdf-archive.com on 15/12/2015 at 12:28, from IP address 197.245.x.x.

The current document download page has been viewed 825 times.

File size: 23.03 MB (15 pages).

Privacy: public file

File preview

p

The AQS Beat

q

Nov/Dec 2015 - 28th Edition

Let’s

p

u

t

p

i

a

wr

& get

festive

q

Dear

Readers

the aqs beat

the

X

Bumper Festive Edition

28th edition - Nov/Dec 2015

1

The AQS Beat

see what’s inside

1

From the creative team

with festive love

Are we taking this crisis seriously enough?

an in-depth look at our water crisis

Keeping Christmas

from the MD’s desk

Celebrating our Winners & Die-Hard employees

awards season

Recycling like you’ve never seen before

our pumps in action

Nov/Dec 2015 - 28th Edition

19

21

23

25

27

The AQS Beat

What we’ve been up to

check out our busy month

Celebrating 2015

year-end functions

Looking back and planning ahead

support dept.

A New Year’s state of mind

new year’s resolutions

Their winning selections

competition time

The old people are without water

sales and marketing dept.

Be green like a pro, conserve H2O

be green like a pro

see what’s inside

3

4

5

7

9

11

13

15

17

Nov/Dec 2015 - 28th Edition

Work hard and Relax harder

commerical dept.

Movember

who will be our mo-king?

2

p

The AQS Beat

with

Nov/Dec 2015 - 28th Edition

Nov/Dec 2015 - 28th Edition

are we taking this crisis

v

i

t

s

e e

f

e

v

q Lo

lease excuse any smudges

you find in this edition - we

have been dancing in the rain!

Speak to any South African

and they will tell you that the heat

is unbearable this season. After

historically low rainfalls and a

record strong El Nino event (the

increase in surface temperature

of the Pacific Ocean), the country

is in the grips of a drought. The

reality of this is scary; read more

on pg 4, 9 and 11, and get tips on

responsible water usage on pg 13.

On a lighter note, this

festive edition of the Beat is packed

3

full of gifts for you; celebrate our

champions with us (pg 7), salute

the Mo Bro’s and Sista’s (pg17),

unwrap some Christmas functions

(pg 21) and tick off your naughty

list with our New Year’s resolutions

on pg 25.

We have a few Christmas

wishes we would like to bestow:

Gerhard, may you have a

memorable Christmas while the

grass grows greener.

Diana, we have sent our request to

Santa that you find your voice in

your Christmas stocking.

André, may you find a way to get

m

e

t’s official; five of South

Africa’s nine provinces

have been declared drought

disaster areas for agriculture

and 2.7 million households are

being affected by the strain on

water supplies. If that is not

reason enough to take notice,

our Minister of Water Affairs

and Sanitation feels that R670

billion is urgently needed to

modernize the country’s water

and waste-water infrastructure

in order to cope with the crisis.

The impact of this

drought on the country, AQS

and our clients is undeniable.

“I’ve never seen the quantities

of pumps we are selling now,

as a result of the drought.”,

says André Nagel, an AQS

director who has been in the

pump industry for 25 years.

The Hazelmere dam

which supplies areas of

KwaZulu-Natal with water is

at a critical 26% (you have

to see it to believe it – watch

the video alongside). Due to

the subsequent severe water

restrictions (some regions

only getting two hours per

day), clients are desperate

to become self-sufficient as

soon as possible. Pumps are

purchased to boost water from

tanks into homes and some are

even using their pools in an

attempt to treat and store water

– “these guys are becoming

creative”.

rid of those heavy metals and keep

your mother happy in the process

(see page 9 for tips).

Peet, we hope all the labels on

your gifts will be in LARGE FONT

this Christmas.

Leon, may the Master of Relaxation

teach you his wise ways amidst

the chaos of the holidays.

And to you, our dear reader, we

wish you safe travels and happy

memories (and loads of gifts!)

over this festive season.

See you again

next year.

Mercifully, KwaDukuza

Municipality is aiding the

community by providing water

for collection (alongside). But

as the public facilities become

unusable and people wait in

endless queues for a day’s

supply of water, one cannot help

but wonder about the impact of

this crisis on local tourism as

thousands of holiday makers

are flooding to the coast.

And the drastic effects

are not exclusive to KwaZuluNatal. AQS Liquid Solutions’

clients in Phalaborwa are

having to drop their boreholes

as underground water levels

take strain too, some boreholes

collapsing completely from the

dry conditions. This dealer also

supplied 18 borehole sets in

one month to the Kruger Park

as they attempt to get water to

their camps, water holes and

other facilities.

As good as it is for

business, let us do what we

can to mitigate the devastating

effects of this drought.

a national crisis

creative team

Cr

P

I

G

eati

a

e

v T

l

?

seriously enough

from

the

The AQS Beat

CLICK OR SCAN

TO WATCH

Hazelmere dam:

Blue = ideal level

Photograph underneath = current level

4

The AQS Beat

Nov/Dec 2015 - 28th Edition

Keeping

our

in action

frompumps

the md’s

desk

t

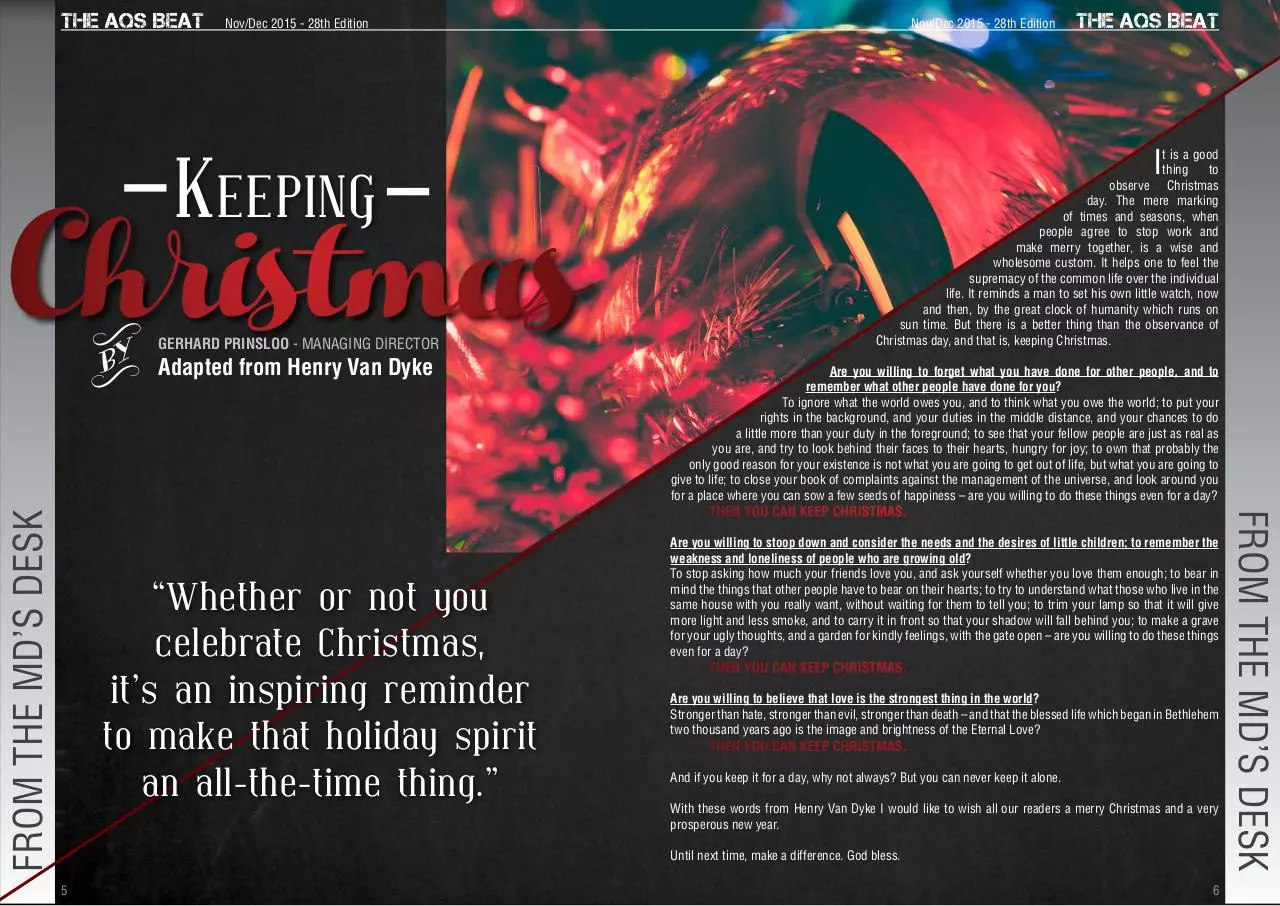

gerhard prinsloo - managing director

Adapted from Henry Van Dyke

“Whether or not you

celebrate Christmas,

it’s an inspiring reminder

to make that holiday spirit

an all-the-time thing.”

The AQS Beat

I

t is a good

thing

to

observe Christmas

day. The mere marking

of times and seasons, when

people agree to stop work and

make merry together, is a wise and

wholesome custom. It helps one to feel the

supremacy of the common life over the individual

life. It reminds a man to set his own little watch, now

and then, by the great clock of humanity which runs on

sun time. But there is a better thing than the observance of

Christmas day, and that is, keeping Christmas.

Are you willing to forget what you have done for other people, and to

remember what other people have done for you?

To ignore what the world owes you, and to think what you owe the world; to put your

rights in the background, and your duties in the middle distance, and your chances to do

a little more than your duty in the foreground; to see that your fellow people are just as real as

you are, and try to look behind their faces to their hearts, hungry for joy; to own that probably the

only good reason for your existence is not what you are going to get out of life, but what you are going to

give to life; to close your book of complaints against the management of the universe, and look around you

for a place where you can sow a few seeds of happiness – are you willing to do these things even for a day?

Then you can keep Christmas.

Are you willing to stoop down and consider the needs and the desires of little children; to remember the

weakness and loneliness of people who are growing old?

To stop asking how much your friends love you, and ask yourself whether you love them enough; to bear in

mind the things that other people have to bear on their hearts; to try to understand what those who live in the

same house with you really want, without waiting for them to tell you; to trim your lamp so that it will give

more light and less smoke, and to carry it in front so that your shadow will fall behind you; to make a grave

for your ugly thoughts, and a garden for kindly feelings, with the gate open – are you willing to do these things

even for a day?

Then you can keep Christmas.

Are you willing to believe that love is the strongest thing in the world?

Stronger than hate, stronger than evil, stronger than death – and that the blessed life which began in Bethlehem

two thousand years ago is the image and brightness of the Eternal Love?

Then you can keep Christmas.

And if you keep it for a day, why not always? But you can never keep it alone.

With these words from Henry Van Dyke I would like to wish all our readers a merry Christmas and a very

prosperous new year.

Until next time, make a difference. God bless.

5

6

our

pumps

in action

from

the md’s

desk

Christmas

Nov/Dec 2015 - 28th Edition

The AQS Beat

e

X

Nov/Dec 2015 - 28th Edition

Nov/Dec 2015 - 28th Edition

rofitable

most pbranch

2015 was an immensely challenging year within a

declining economy and a country in the grips of a

national drought. And yet AQS achieved new records

monthly. These men and women of the AQS Family

made it all possible. Congratulations and thank you

for your dedicaion and hard work!

pf

d

e

X

long service

o

awards

AQSLT Steelpoort

10

These awards are

given to the AQS

Family members

who are dedicated

and truly stick it out

for the long run.

The following sales

representatives

have joined the

Millionaires’ Club

for the 2014/2015

financial year.

o

Hennie

Ackermann

Danie

Lombaard

Peet Els

q’

millionaires

q

certificates

years

o

The AQS Beat

Stephen

Bellingham

f

5

Annatjie

Koekemoer

Varsha

Mackerdhooj

Ruth

Maphumulo

t

growth

in

and

utilisation

Yp

of

otential

Lee Moodley

7

Brent Read

Chris du Toit

Fortuin

Warries

Michael

van Zyl

Rudy van der

Merwe [x2]

highest

turnover

turnover

Y

o

Shawn

van Eeden

highes

Clintin

Janse van

Rensburg

Quintus

Dippenaar [x2]

Clintin

Janse van Rensburg

8

awards season

Jim-Allen

van Deventer

o

awards season

years

The AQS Beat

et’s face it, we can no longer rely on good old

precipitation to provide for us (contrary to what

they teach us in biology class). As a growing

species we are demanding and wasteful, and this

planet’s natural resources are clearly not as prolific,

forgiving or responsive

to divine intervention

as we have been telling

ourselves. However, the

bright side to our continual industrial advancement is

that technologies have improved and been developed

to combat the issues caused by this very growth. Here

is a glimpse into such an endeavor and the people

behind it.

Waste water from mines is listed as one of

the major sources of water wastage (especially in

South Africa with an economy that is so driven by

the mining sector). The water that is disposed of after

mining operations, or that seeps out from disused

mines, is highly acidic and contains a large amount

of heavy metals. This “poisonous cocktail” pollutes

the surrounding environment, often irreparably.

According to the Environmental Forum of Africa

(IFAT) a range of solutions are being supplied by

international environmental technology companies

to treat mine water in South Africa. These methods,

such as ventilation, ion-exchange processes, reverseosmosis and nano filtration, generally aim to neutralize

the pH values and remove metals from the water, still

leaving behind the salts. There are only a few “flagship

projects” which are succeeding in making this water

truly potable, and thus playing a potentially vital part

in alleviating the country’s water shortage. Watercare

Mining, an AQS client, is one of these pioneers.

Watercare Mining runs a plant operations and

maintenance division that is geared towards recycling

mine’s waste water and then selling this water back

to the mines as a potable resource. AQS recently

supplied 13 pumps with their control systems (VSD’s)

for a plant which was commissioned at a mine in

Westonaria. This is the first such plant in the country to

use Crystalactor technology (the license of which was

acquired from a company in Holland, after several years

of negotiation). What makes this so impressive (apart

from the name)? The technology is superior in that

it performs selective removal of compounds through

crystalisation within the reactor of the fluidized-bed

(i.e. pellet reactor), all without a footprint. Yes, this is

a patented zero-waste water treatment technology.

As

the

fifth mine water

recycling

plant

to be developed,

commissioned and maintained by Watercare Mining,

and the first to use the new technology as well as AQS

9

Nov/Dec 2015 - 28th Edition

The AQS Beat

pumps, the plant is operating at 100% and meeting

all expectations of efficiency. The mine is happily

benefiting from the cost saving of purchasing the

recycled water as opposed to the municipal supply, all

the while reducing its environmental discharge.

Peter Marks, project engineer,

explains that he chose

to switch from other

pump suppliers to

AQS foremostly for

cost-saving

purposes

and

also for

the level of

service. Our

vertical multistage

(DL’s) and end

suction pumps (DZA’s)

are used for a variety of

purposes on the plant;

from pumping the

decarbonated water into

the lime slurry maker,

to transferring the

water between stages

and then feeding it

back into the main

line at high

pressures.

A few plans had to be

made to accommodate stock

restrictions and deadlines,

but Peter did not hesitate in his

affirmative response to using AQS,

and Leon Fourie, for future projects;

“Absolutely. Every relationship gets

bumpy at times, but I am a loyal person and we

have a good thing going.”

Leon describes this project as; “A real

challenge. It was the first time we used our new model

of variable speed drives to monitor and control the

pump’s flow output, instead of the more conventional

monitoring of pressure. And we got it right!”.

This is where we applaud a job well done

and then rally

forces for the

next onslaught

against the war

on drought, because “caring” is no longer a luxury, it

is a prerequisite for our survival.

our pumps in action

our pumps in action

L

Nov/Dec 2015 - 28th Edition

10

The AQS Beat

Nov/Dec 2015 - 28th Edition

20

200

20

100

S

T H E

O L D

PEOPLE

100 FT

30.5 M

70 FT

21.3 M

ARE WITHOUT

50 FT

15.2 M

20

30

W

R

30 FT

9.15 M

20

20

B Y

S N Y M A N

20 FT

6.1 M

T

P E E T

itting behind my desk in the sales office, someone from whom you have learned so much.

I read an email on my phone. “Why are

you holding that phone so far away from As we carefully, considering the old boys need to

the eyes?”, asks a voice behind me.

focus, walk down the stairs to the test bay area, he

explains that the residents are very dependent on

I look up and smile. “My arms are still long enough, the water supply. Water infrastructure is becoming

unlike you old guys”, I respond. “Good morning, unreliable and self-sustaining maintenance is

Uncle John”. I offer my hand as I get up to greet important nowadays. The retirement village is

an old friend. John, a longtime colleague from the about an hour’s drive out of the city and John

pump industry who is now happily retired, has complains about the fact that there is no longer

come to visit. He is a man with vast experience in anybody who can reliably supply the people in the

the game and in his younger days flew his plane area with pumps. The little community has limited

around the country to commission process plants. storage capacity and the tanks are empty at this

He introduces me to the other gentleman; fellow stage. Water is supplied to the residents in two

resident of the retirement village and an electrical sections at different times so that everybody has

man I am told. Pleasantries aside I ask what a fair share of water during the day. The sense of

brings them to town. “The old people are without urgency is understood. We have to make a decision

water” is the explanation from these two guys who so that they can get back and do the installation. I

are comfortably over seventy. “Our supply borehole know of much younger guys who would shudder at

pump has stopped working. We suspect motor the thought of pulling out and reinstalling their own

failure. Hope you can help? We have brought the borehole pump set.

complete pump set for you guys to look at.” It is

always flattering if one can offer assistance to The technical crew has already assembled the

11

200 FT

61 M

20

50

A

E

The AQS Beat

pump with a test motor. “Let’s drop this in the tank

and see if the wet-end is still functioning”. The name

plate is unreadable so we have to find another way

to determine the pump’s capacity. “How long does

it take to fill the tanks normally?”, I ask. “Around 6

hours”, is the response. Ok, that gives us 40l/min.

Now the head (pressure) capability. Counting the

stages of the pump gives us a starting point. The

guys in the shop run the pump while we get some

curves to check the performance against. The lack

of performance quickly becomes obvious as the

unit is put through its passes on the rig. The wetend seems to be worn and a teardown confirms the

diagnoses. Up-thrust damage is evident and with

curve in hand I ask how deep the hole is seeing

that the pump they have been supplied with can

do a 120m lift. The two old guys look at each other

and concur that the pump is hanging at a depth

of 140m. “Mmm…….and the water level?” “Oh no,

that is around 8m from ground level. I measured

that myself with some rope and a spanner”, John

answers. This doesn’t make sense and I suspect

that once again someone has selected a pump not

suited for the application.

A new pump combo is selected by the team and

assembled. Joining kit, motor cooling sleeve,

pressure gauge, the works. Smiles all round

as I meet up with them in the sales office. “My

goodness, we even got a healthy discount!” John

smiles, obviously glad about the decision to come

to us. “Pensioner Tuesday”, comments the Internal

Sales Crew Leader. “You guys get bus fares at half

price and free coffee on Wednesdays at the mall,

so dammed if we don’t also offer some added value

to old folks.” And everyone joins in the light-hearted

moment. After a few electrical connection drawings

and advice on phase balancing to the sparky, the

guys are off.

A later message from the village is that all is well

and the set is working smoothly…..it seems that

even a pump company like AQS can bring joy to

people over this festive season.

12

sALES & mARKETING dEPT.

sALES & mARKETING dEPT.

20

70

Nov/Dec 2015 - 28th Edition

The AQS Beat

June 2015

Nov/Dec

2015

- 23rd

- 28th

Edition

Edition

Nov/Dec 2015 - 28th Edition

Our Top tips

3

3

B E GREE N

conserve

TO SAVE

WATER

1

T0

AVERAGE

OF

23

YOUR

SHOWER

3%

FOR HUMAN

CONSUMPTION

13

11TIMES

LESS

4500

FIXING

LEAKS IN A

LITRES A

TOILET

MONTH

4

WATER YOUR GARDEN

AT THE TIMES OF

LEAST

EVAPORATION

WATER

WASH ONLY FULL LOADS IN

YOUR DISHWASHER AND

WASHING MACHINE.

5

IN THE EARLY MORING

OR LATE EVENING.

INSTALL

A DUAL-FLUSH TOILET

OR

IF IT IS YELLOW

LET IT MELLOW

6

DON’T

LEAVE

WATER

RUNNING FOR

SHAVING

BRUSHIN

G

97%

Polar Ice Caps

Q

Of that 3%, 2/3 is

frozen in glaciers

and polar ice caps,

leaving approximately

1% ready for human

consumption.

7

INSTALL A COLLECTION TANK TO THE

GUTTERS OF YOUR HOME.

THE COLLECTED WATER

CAN BE USED FOR

TOILET WATER

& GARDENING

(

WASHING

ES

SH

DI

OF ALL

WATER

IS FIT

USES

COULD SAVE

THE SINK

LL

)

FI

R

ONLY

A DISHWASHER

R TE E T H

e

of th er,

%

70

at

ugh ce is w s

o

h

t

i

a

Al

surf t water

s

’

h

t

a

g

ear

of th , leavin

%

97 water

for

salt ere 3% r.

a m h wate

fres

3

LITRES A DAY

2

CHECK AND REPAIR LEAKS

FROM TOILET, TAPS AND PIPES

bE GREEEN LIKE

contents

A PRO

e

G L O B A L C RI SI S

10MIN.

U

YO

bE GREEEN LIKE A PRO

FROM

5 MINUTES

COULD

SAVE AN

REDUCING

After one of the driest rainfall seasons on record, South Africa is in the grip of a severe

drought. This has placed a strain on water supplies across the country, affecting 2.7

million households. The hardest hit are those living in rural areas, where residents have

to collect water in buckets once a day. With the drought persisting, South Africa has now

declared five of its nine provinces a drought disaster for agriculture. Thus, it has become

neccessary to conserve our limited water resources. Read about some of the easy ways

we can conserve water on a daily basis.

The AQS Beat

8

USE BUCKETS

FOR CLEANING

FLOORS, CARS

& WINDOWS

14

The AQS Beat

Nov/Dec 2015 - 28th Edition

Work hard

Nov/Dec 2015 - 28th Edition

y

RELAX HARDER

T

he end of the year is drawing near and I am tired. Not from lack of sleep, but

from the outside “noise” which is getting harder to control. It is that time of

the year when you start to get nervous about how short your holiday will be

versus how much relaxation has to be done to restore the levels of sanity needed to

tackle the next onslaught.

I keep telling myself that this time I’m going to do it right. I’m going in prepared.

No last minute stuff and the obvious place to start searching for advice and ideas

is...the internet. Advice is plentiful and ranges from spending time with your pets

to taking dance lessons with your partner. Most of the advice I found involves a

partner, so I would recommend ignoring these types of sites. The bottom line is;

most people agree that the key to relaxation is to learn to do nothing, to embrace

controlled laziness. Complete relaxation is a skill that is difficult to acquire

and gets more difficult the older you get.

The best advice I came across was from a Zen site, which explained relaxation is

the result of succeeding in doing nothing. The steps towards achieving relaxation

include finding a place where you are completely isolated and practicing

“doing nothing” for 5 to 10 minutes. The better the place, the better the result. A

positive outcome of mastering the nothingness of relaxation is that you essentially

work smarter (when you do work). The site also mentioned that a

good reference is watching your dog or cat when napping.

They would normally get very comfy and then do nothing for a long period of time.

This process is repeated many times a day.

commercial dept.

Commercial dept.

lEON FOURIE - COMMERCIAL DIRECTOR

The AQS Beat

I’m fortunate enough to be spending my relaxation time at the coast this coming

holiday. I intend to find that place to be alone and attempt to try and do/think about

nothing and master the nothingness of relaxation. My hope is that our readers will

also find a nice, quiet place this holiday to help test out this

interesting theory with me.

“Half our life is spent trying

to find something to do with

the time we have rushed

through life trying to save.”

Will Rogers

15

I love quotes and came across this little gem:

“Half our life is spent trying to find something to do with the time we have

rushed through life trying to save.” - Will Rogers, Autobiography, 1949

16

Download AQS Beat Nov Dec 2015

AQS Beat Nov Dec 2015.pdf (PDF, 23.03 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000324269.