HIOKI RM3544 ENG (PDF)

File information

Title: RESISTANCE METER RM3544, RM3548

Author: HIOKI

This PDF 1.7 document has been generated by Adobe InDesign CS5.5_J (7.5.3) / Adobe PDF Library 9.9, and has been sent on pdf-archive.com on 25/12/2015 at 07:51, from IP address 5.18.x.x.

The current document download page has been viewed 913 times.

File size: 5.59 MB (12 pages).

Privacy: public file

File preview

RESISTANCE METER RM3544, RM3548

Component measuring instruments

Easy to use with high-accuracy

Resistance Meters for Production Lines and MRO

The Resistance Meters RM3544/RM3544-01/RM3548 can measure the winding resistance of devices

such as motors and transformers, the contact resistance of power contacts (relays and switches), and the

DC resistance of fuses, resistors, and substrates such as conductive rubber and sheets. It does so quickly

and at a high level of accuracy using four-terminal measurement.

The RM3544/RM3544-01 is well suited to use for adjustment and testing on production lines as well

as acceptance inspections, while the RM3548 comprises a portable solution for measuring resistance

values ranging in magnitude from microohms to megohms, making it ideal for use in production, maintenance, repair and operation of large equipment.

2

Perform resistance measurement with an ideal combination of equipment

depending on your component or equipment and test conditions.

Applications

Probes suited to manual measurement on production lines

Motors, solenoids, choke coils, transformers, wire harnesses

Contacts, wire harnesses, relay contacts, switches

4 -TERMINAL LEAD

L2104

CLIP TYPE LEAD

L2101

Conductive rubber, paint

Fuses, resistors, heaters, wires, welds

PIN TYPE LEAD

L2102

Large motors, large transformers

PIN TYPE LEAD

L2103

Probes suited to DC measurement

of the chassis and bodies of large

equipment

Temperature rise tests (Motors, choke coils, transformers)

4 -TERMINAL LEAD

9453

CLIP TYPE LEAD

L2107

PIN TYPE LEAD

9465-10

Vehicle grounding lines, conductivity of aircraft fuselages

PIN TYPE LEAD

9772

LARGE CLIP TYPE LEAD

9467

A Full Line-up of HIOKI Resistance Meters

to Suit Your Measurement Range

0.1μΩ

0.01μΩ

0.01μΩ

0.1μΩ

1μΩ

RM3544/RM3544-01

RM3548

RM3545

1.2kΩ

RM3543

RM3542

1kΩ

3.5MΩ

3.5MΩ

1200MΩ

120MΩ

DSM-8104

3 ×1016Ω

3

Robust specifications in a compact package

RESISTANCE METER RM3544/RM3544-01

High-accuracy bench-top

resistance meter

for both manual operation and

integration with automatic lines

Basic accuracy : 0.02%

Max.resolution : 1μΩ

Max. measurable current : 300mA

Measure from 0.000 mΩ (@ 300 mA) to 3.5 MΩ

Probe for guard jack use and increased

measurement current yield an instrument that’s

more resistant to noise.

Optional LED COMPARATOR ATTACHMENT and

high-volume judgment tones combine to ensure

PASS/FAIL judgments are communicated reliably

in the noisy environment of the production floor.

EXT I/O interface with NPN/PNP support can

accommodate a variety of automated production

lines (-01 model).

RESISTANCE METER RM3548

High-accuracy portable

resistance meter

Basic accuracy : 0.02%

measures from µΩ to MΩ

Max. measurable current : 1A

Max.resolution : 0.1μΩ

Measure from 0.0 µΩ (@ 1 A) to 3.5 MΩ

Temperature correction

Easily record up to 1,000 data points in

memory simply by applying the instrument’s

probes.

Smoothly capture temperature-rise test data

using interval measurement.

Portable design is ideal for maintenance and

testing of large equipment.

Generally, the resistance of copper wiring changes with temperature

by 0.4% per degree Celsius. The RM3544/RM3544-01/RM3548

provides a temperature correction function to convert the observed

resistance value Rt at the current temperature t to the resistance

value Rto at the reference temperature t0.

*Requires temperature sensor (Z2001 or Z2002).

Reference temperature setting range:-10 ℃ to 99.9 ℃

Temperature coefficient setting range:-9,999 ppm to +9,999 ppm

Resistance

value

Rt

R t0

Correction

t0

t

Temperature

4

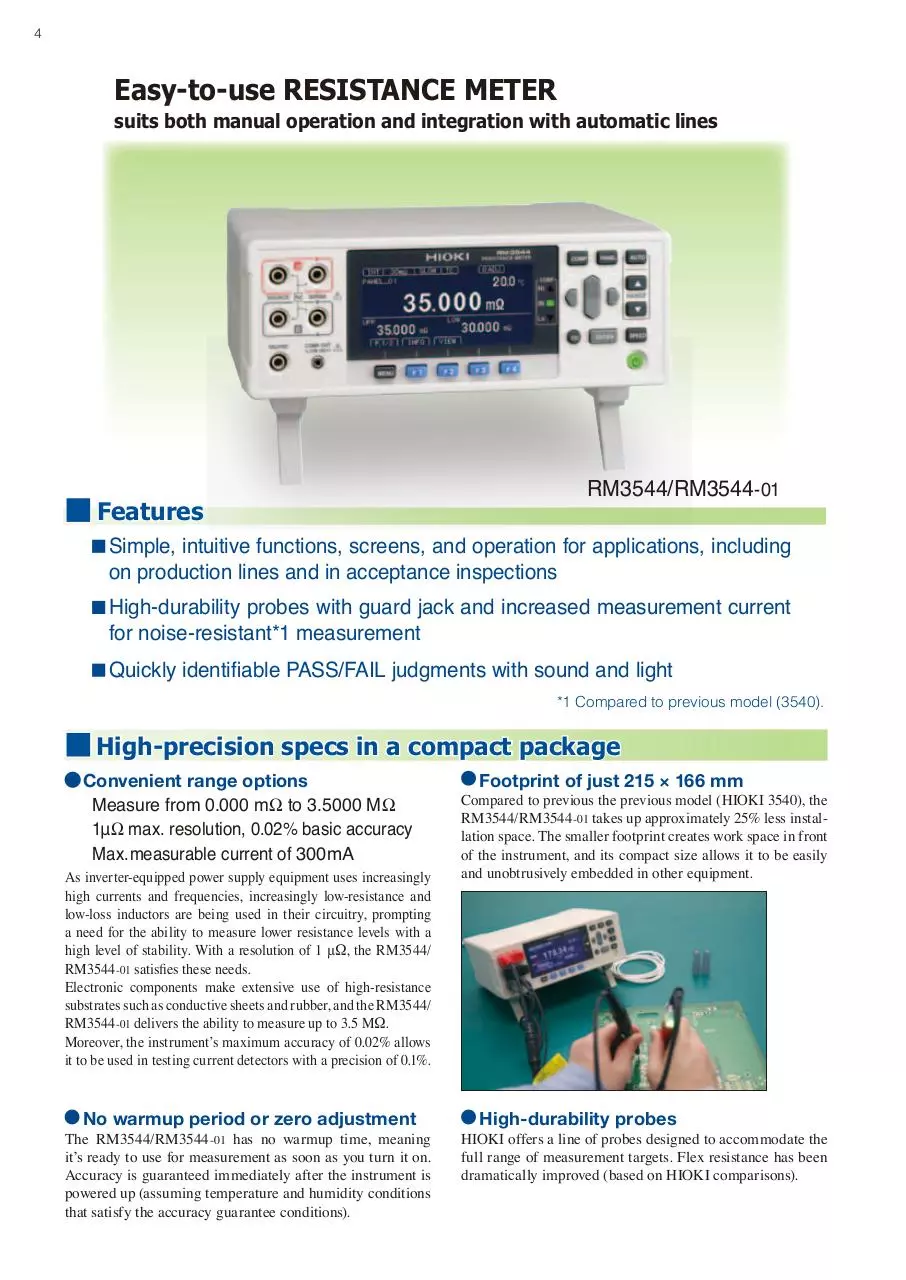

Easy-to-use RESISTANCE METER

suits both manual operation and integration with automatic lines

Features

RM3544/RM3544-01

Simple, intuitive functions, screens, and operation for applications, including

on production lines and in acceptance inspections

High-durability probes with guard jack and increased measurement current

for noise-resistant*1 measurement

Quickly identifiable PASS/FAIL judgments with sound and light

*1 Compared to previous model (3540).

High-precision specs in a compact package

Convenient range options

Measure from 0.000 mΩ to 3.5000 MΩ

1μΩ max. resolution, 0.02% basic accuracy

Max. measurable current of 300mA

As inverter-equipped power supply equipment uses increasingly

high currents and frequencies, increasingly low-resistance and

low-loss inductors are being used in their circuitry, prompting

a need for the ability to measure lower resistance levels with a

high level of stability. With a resolution of 1 μΩ, the RM3544/

RM3544-01 satisfies these needs.

Electronic components make extensive use of high-resistance

substrates such as conductive sheets and rubber, and the RM3544/

RM3544-01 delivers the ability to measure up to 3.5 MΩ.

Moreover, the instrument’s maximum accuracy of 0.02% allows

it to be used in testing current detectors with a precision of 0.1%.

No warmup period or zero adjustment

The RM3544/RM3544-01 has no warmup time, meaning

it’s ready to use for measurement as soon as you turn it on.

Accuracy is guaranteed immediately after the instrument is

powered up (assuming temperature and humidity conditions

that satisfy the accuracy guarantee conditions).

Footprint of just 215 × 166 mm

Compared to previous the previous model (HIOKI 3540), the

RM3544/RM3544-01 takes up approximately 25% less installation space. The smaller footprint creates work space in front

of the instrument, and its compact size allows it to be easily

and unobtrusively embedded in other equipment.

High-durability probes

HIOKI offers a line of probes designed to accommodate the

full range of measurement targets. Flex resistance has been

dramatically improved (based on HIOKI comparisons).

5

Advanced functionality that’s as easy to use as it is easy to understand

Measurement jacks with guard jack

By connecting a probe to the guard jack, you can minimize the

effects of external noise on measurements.

Simple control over basic settings

Range and measurement speed can be controlled directly.

Loud, user-selectable judgment tones

High-volume judgment tones of at least 85 dB inform the

operator of test results, ensuring that they remain audible

even in the vicinity of noisy machinery. The ability to

choose from various tones ensures operators won’t confuse

judgment results on lines where multiple RM3544 units are

in use.

LED COMPARATOR ATTACHMENT (Option)

The LED Comparator Attachment indicates judgment results

with green and red LEDs, eliminating the need to look at the

instrument’s screen and increasing work efficiency. Since the

lamps do not light up when the measurement leads are open, the

attachment can also be used to verify the connection status.

Green light

IN state

Red light

HI/LO state

Material- and temperature-independent temperature correction function

The temperature correction function can be used to convert resistance values that vary with

the ambient temperature to a reference value at a reference temperature using the Temperature

Sensor Z2001 and a user-specified resistance temperature coefficient.

Scaling

The scaling function can be used to convert resistance values into physical properties such as length.

Conversion formula : Rs = A × R + B

A, B : Constants, R : Measurement value

Rs : Resistance value

Intuitive, graphical LCD

Panel save and load functionality for

up to 10 sets of parameters

Panel save and load functionality provides the ability to save

and subsequently load up to 10 sets of instrument setting

conditions for range, comparator, and other parameters.

Naming each set of panel data lets you make setup changes

among production lots and lines smoothly and effortlessly.

Comparator Function

The comparator function compares measured values to a

previously set reference value or range and then displays

and outputs the judgment result. The RM3544-01 can also

output comparator results via its EXT I/O interface.

6

Acquiring measurement results (data) (RM3544-01)

RM3544-01 rear panel

RS-232C/PRINTER

EXT I/O polarity

(Select NPN/PNP)

EXT I/O

Pr ote c t i ve f us e

for measurement

circuitry

Maintenance jack for HIOKI use only

(This jack is provided for maintenance use.

It cannot be used by the customer.)

USB

Temperature sensor jack

*The RM3544 does not include EXT I/O or communications interfaces (RS-232C or USB).

Connecting the instrument to a computer

via RS-232C or USB

• The full range of RM3544 -01 functionality can be controlled from

a computer, which can also be used to acquire measurement results.

(This capability does not include turning the instrument on and off

or configuring certain interface settings.)

• By connecting the instrument to a commercially available RS-232C

printer, it you can print measured values, including judgment results.

• Measured values can be automatically output. By using the

instrument’s USB keyboard mode, measured values can be

entered into applications such as spreadsheets and text editors

without the need to install a special USB driver in the computer.

• The sample PC application provides functionality for capturing

data based on trigger signals, performing interval measurement,

conducting communication tests, and loading captured data into

Microsoft® Excel or outputting it as a CSV file. The application can be downloaded from Hioki’s website (http://www.hioki.

com).

USB/RS-232C

Applications screen

Communications Monitor screen

Communications monitor function for smooth

system development

The communications monitor function displays communications data

(received commands and sent data) on the screen, providing valuable

support for programming of programmable logic controllers (PLCs).

Enlarged view of

communications data

Universal power supply for robust accommodation of supply voltage fluctuations

and automatic power supply frequency

detection (RM3544/RM3544-01)

Measuring in sync with the power line frequency is important for

achieving accurate measurements. To avoid measurement problems due to incorrect settings, the power line frequency is automatically sensed and selected (50 or 60 Hz).

The universal AC input (90 to 264 V) is practically unaffected by

voltage fluctuations, so stable measurements are possible even in

poor power environments.

50 Hz / 60 Hz

90 to 264 V

7

Easy integration into automatic testing equipment (RM3544-01)

High-speed, comprehensive productivity

support

Measurement time*1

Measurement speed (ms)

FAST

MED

SLOW

• The RM3544-01 delivers the speed demanded by automatic testing equipment at a sophisticated level. The entire process from the

start of measurement to outputting of the judgment result takes as

little as 18 ms. One cycle of operation, lasting from measurement

to judgment output, completes within this time.

• The RM3544-01 supports RS-232C data communications at up to

115.2 kbps.

• The instrument’s USB interface can also be used.

• The EXT I/O output mode can be switched between judgment

mode and BCD mode.

50Hz

60Hz

21

18

101

401

Tolerance: ±10% ±2 ms

*1 With TC set to ON and the comparator set to ON

Functionality for verifying the EXT I/O connection status and testing EXT I/O

In addition to allowing you to check EXT I/O signal input on the instrument’s screen, this functionality allows you to turn output signals

on or off as desired. This capability simplifies verification work during PLC programming.

EXT I/O test function screen

When designing a control system using the EXT

I/O interface, be sure to read

the instruction manual and check the necessary

technical information.

Handler (EXT I/O) interface

The handler interface (EXT I/O) is isolated from measurement circuitry, control circuitry, and the protective ground (chassis ground),

providing a high level of noise resistance.

Example of Typical

Input Signals

Example of Typical EXT I/O Timing (EOM output hold)

TRIG

0ADJ

KEY_LOCK

BCD_LOW

: External trigger

: Zero-Adjust

: Key-Lock

: Lower digit specification when

set to BCD output

LOAD0 to LOAD3 : Panel number to load

IN0, IN1

: General-purpose input pins

ON

TRIG

OFF

t0

t1

OFF

During processing

Measurement

processing

t2

t3

INDEX

OFF

EOM

OFF

ON

OFF

HI,IN,LO

ERR,BCDm-n

OFF

ON/OFF

OFF

OFF

ON

t4

Output Signals

HI, IN, LO

EOM

INDEX

ERR

HILO

BCDm-n

t0 : Trigger pulse ON time (0.1 ms or more)

t1 : Trigger pulse OFF time (1 ms or more)

t2 : Measurement start time (max. 1 ms)

t3 : Capture processing time ; FAST(50Hz): 20.0 ms, FAST(60Hz): 16.7 ms, MEDIUM: 100 ms, SLOW: 400 ms

t4 : Calculation time ; 1 ms

EXT I/O Input and Output Circuits

RM3544-01

2kΩ

EXT I/O polarity

(Select NPN/PNP)

Output Circuit

RM3544-01

10Ω

1kΩ

ISO_COM

EXT I/O

MODE

SELECTOR

Output

Input

PNP

NPN

Internally Isolated

Common

RNG_OUT0 to

RNG_OUT3

ISO_5V

ISO_COM

EXT I/O Electrical Specifications

A switch on the rear panel is used to toggle the input signal polarity between NPN (sink output support) and PNP

(source output support) settings depending on the PLC

common polarity.

Input Circuit (Case of NPN type)

OUT0 to OUT2

: Comparator Hi, IN, LO

: End of Measurement

: End of Import

: Measurement Fault Output

: Outputs HI or LO when set to

BCD output.

: Outputs the nth bit of the mth

digit when set to BCD output.

: General-purpose output pins

when set to judgment mode

: Outputs range information when

set to BCD output.

: Internally Isolated 5 V

: Internally Isolated Common

Max. 50 mA DC

Zener voltage

= 30 V

ISO_COM

Internally Isolated

Common

Inputs:

Photocoupler isolation: Non-voltage contact inputs

(support for current sink output)

Input ON: Residual voltage: Max. 1 V @4 mA

Input OFF: Open Max. 100 μA

Outputs:

Photocoupler-isolated open drain output (no-polarity)

DC30Vmax, DC50mAmax/ch

Residual voltage: Max. 1 V @50 mA, or 0.5 V @10 mA

External power output:

Output voltage: Sink output support: 5.0V±10%,

Source output support: -5.0V±10%

Max. output current: 100mA

8

High-accuracy portable RESISTANCE METER

measures from µΩ to MΩ

RM3548

Features

High-precision specs in a portable package(high accuracy of 0.02% rdg.)

Design is ideal for maintenance and testing/measurement of large equipment.

No warmup period or zero adjustment required.

Dramatically improved overvoltage resistance (protection up to 70 V DC)

High-precision specs in a portable package

Expansive range options

Measure from 0.0 μΩ to 3.5000 MΩ

0.1μΩ max. resolution, 0.02% basic accuracy

Max. measurable current of 1A

Continuity and resistance measurement

in large transformers, motors, and power

supply equipment

The RM3548 uses a high current of 1 A to measure lower

resistance values more reliably at a resolution of 0.1 μΩ in

applications including measuring resistance in large transformers and motors as well as wiring, busbars and connections in power supply equipment.

Verification of continuity of ground

lines in automobiles and fuselage

welds and caulking in aircraft

The RM3548 can be used to check ground connections*

in automobiles and fuselage welds and caulking in aircraft using a measurement current of 300 mA (300 mΩ

range).

9

Portable, easy to use, and easy to understand

Design is ideal for maintenance and testing/

measurement of large products

The included strap can be looped around the neck to support the instrument, leaving the operator’s hands free to hold probes for measurement. The meter uses eight AA alkaline batteries, which provide

enough power for approximately 10 hours of testing under normal

operating conditions. (Operating times vary with measurement conditions.)

Auto-hold and auto-memory functionality

The RM3548 features auto-hold and auto-memory functionality to

automatically hold and record data simply by placing the probes in

contact with the desired measurement location. This functionality

allows measured values to be recorded automatically as soon as

they stabilize without the need for the user to operate any switches.

LED COMPARATOR ATTACHMENT

By installing the LED COMPARATOR ATTACHMENT close to a

probe, you can capture judgment

results without moving your eyes

away from the measurement location and probe.

No zero adjustment

Accuracy is defined without any need to perform zero-adjustment.

Measurement can be performed as soon as the instrument is turned on.

Dramatically improved overvoltage resistance

Green light

IN state

Red light

HI/LO state

Protection is provided against overvoltage input of up to 70 V, preventing damage caused by connecting the instrument to an electrical

charge or by the effects of the counter-EMF from inductance.

Offset Voltage Compensation(OVC)

Thermal EMF occurs at the contact point of different metals.

This voltage affects measurements, and if large enough, can cause

measurement errors. The offset voltage compensation function

minimizes the effect of thermal EMF to maintain measurement

accuracy. Particularly when measuring low resistances where the

detection voltage is small, and during low-power resistance measurements, OVC is essential to maintain accuracy.

Length conversion function

By setting a resistance value per meter, it is possible to convert

resistance values into lengths. This capability is useful when managing cable inventory or estimating PCB pattern lengths.

Circuit protection detection state

(Alerts the operator to overvoltage

input with a screen display and an

audible warning.)

Acquire measured values recorded in the

instrument’s memory over a USB connection

By connecting the RM3548 to a computer with a USB cable*, you

can download measured values stored in the instrument’s memory.

*Since the RM3548 provides a mass storage class (read-only) USB

interface, there is no need to install special driver software on the

computer

Temperature conversion function and interval measurement:

Useful in temperature-rise testing

Temperature increase (Δt) is obtained and displayed by converting resistance measurements and ambient temperature.

The maximum temperature increase needs to be determined when current is applied especially for verifying motor

windings or transformers.The interval measurement function can be used to take measurements at a user-specified

interval from the start of measurement. Since measured values can be recorded in the instrument’s memory, the

maximum temperature can be easily estimated.

*The temperature conversion function cannot be used simultaneously with the temperature correction function and length conversion function.

➀ When a motor or coil has thermally stabilized at room temperature,

measure the resistance (r0) and ambient temperature (t0) before applying

current.

➁ Excite the coil, and when the temperature increase appears to saturate,

remove the excitation.

➂ After removing excitation, determine the temperature (∆t1 to ∆tn) from

the resistance (rt) measured at each specific time (t), and the ambient

temperature.

➃ Project the curve through the collected temperature data (∆t1 to ∆tn) to

estimate the maximum temperature increase (∆t).

Download HIOKI RM3544 ENG

HIOKI_RM3544_ENG.pdf (PDF, 5.59 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000326712.