KODAK OPG K9000 3D ERROR MESSAGE ed02 en (PDF)

File information

Title: SM712_K9000 3D_SERV.book

Author: 10106120

This PDF 1.3 document has been generated by FrameMaker 7.0 / Mac OS X 10.12.1 Quartz PDFContext, and has been sent on pdf-archive.com on 18/12/2016 at 08:16, from IP address 120.140.x.x.

The current document download page has been viewed 5859 times.

File size: 666.64 KB (87 pages).

Privacy: public file

File preview

Chapter 7

ERROR MESSAGES

WARNING

You MUST switch off the unit before removing the covers. ONLY an

approved Trophy technician is qualified to carry out any intervention on

the unit while it is switched on and while the covers are removed. NO

unqualified person must approach the unit in the above case.

E 1: Handswitch was Released Before the End of

Exposure

Definition of the Cause

The microprocessor detects premature release of exposure button of the x-ray remote control

before the end of acquisition.

Solution of the Cause

Possible Cause:

The user has released the exposure button prematurely.

Remarks:

If the exposure button is released shortly before the end of the acquisition cycle, the

image can be saved.

Fault Identification:

Solution:

•

•

Possible Cause:

Save the image if possible.

Relaunch the acquisition and hold the exposure button until the end of the

acquisition cycle.

•

The exposure button is defective.

The door safety contact is defective.

• The wiring of the x-ray remote control is defective.

•

Remarks:

Fault Identification:

•

The fault occurs when the exposure button is activated.

The problem occurs frequently and at random intervals.

• Check the wiring, the exposure button and the contacts.

•

Solution:

Replace the defective component.

KODAK 9000 and KODAK 9000 3D Extraoral Imaging System_Service Guide (SM712)_Ed 02

7–1

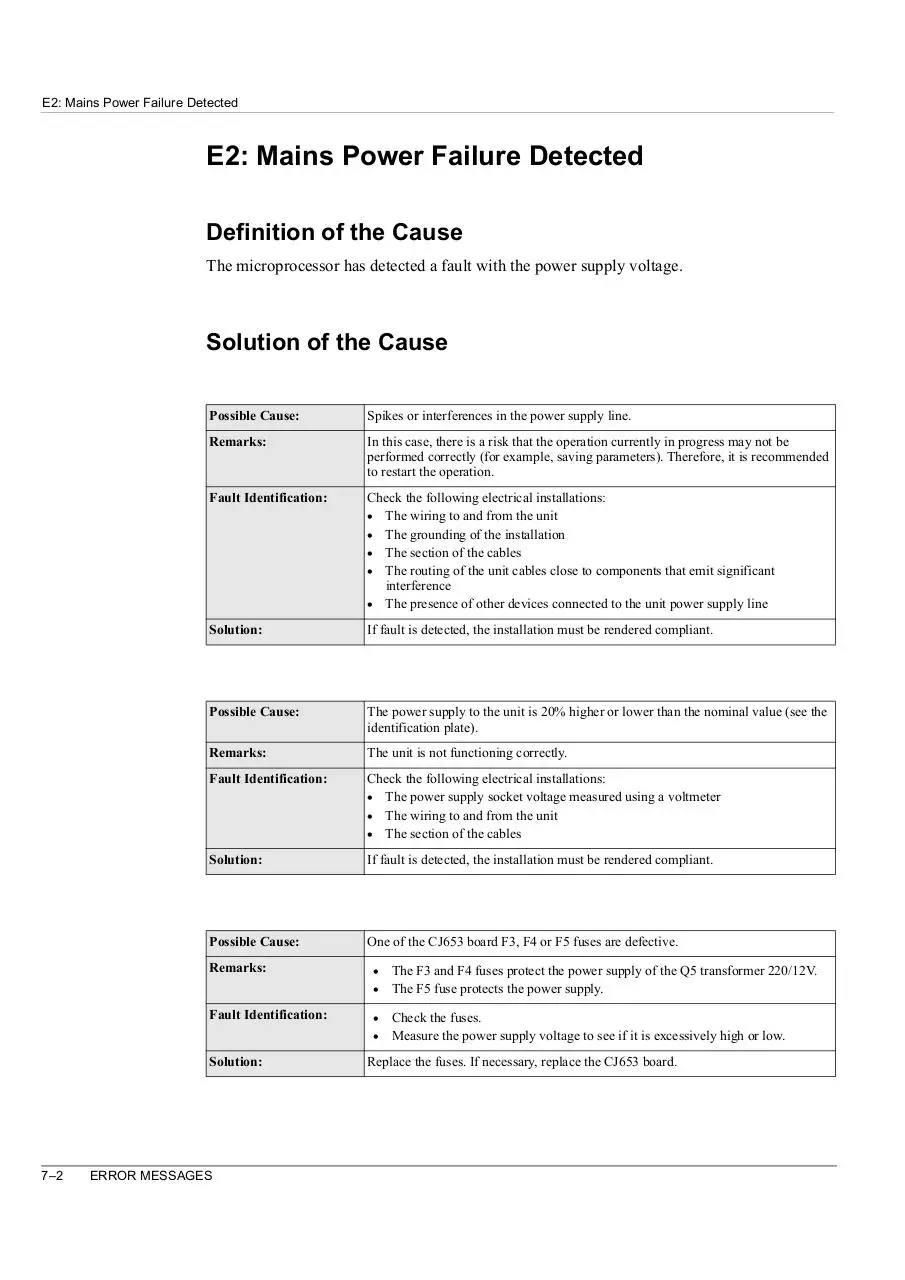

E2: Mains Power Failure Detected

E2: Mains Power Failure Detected

Definition of the Cause

The microprocessor has detected a fault with the power supply voltage.

Solution of the Cause

Possible Cause:

Spikes or interferences in the power supply line.

Remarks:

In this case, there is a risk that the operation currently in progress may not be

performed correctly (for example, saving parameters). Therefore, it is recommended

to restart the operation.

Fault Identification:

Check the following electrical installations:

• The wiring to and from the unit

• The grounding of the installation

• The section of the cables

• The routing of the unit cables close to components that emit significant

interference

• The presence of other devices connected to the unit power supply line

Solution:

If fault is detected, the installation must be rendered compliant.

Possible Cause:

The power supply to the unit is 20% higher or lower than the nominal value (see the

identification plate).

Remarks:

The unit is not functioning correctly.

Fault Identification:

Check the following electrical installations:

• The power supply socket voltage measured using a voltmeter

• The wiring to and from the unit

• The section of the cables

Solution:

If fault is detected, the installation must be rendered compliant.

Possible Cause:

One of the CJ653 board F3, F4 or F5 fuses are defective.

Remarks:

•

•

Fault Identification:

•

•

Solution:

7–2

ERROR MESSAGES

The F3 and F4 fuses protect the power supply of the Q5 transformer 220/12V.

The F5 fuse protects the power supply.

Check the fuses.

Measure the power supply voltage to see if it is excessively high or low.

Replace the fuses. If necessary, replace the CJ653 board.

E2: Mains Power Failure Detected

Possible Cause:

Cancellation of +12 V

Remarks:

The U20 controller of CJ732 detects power supply voltage inferior to 12V.

Fault Identification:

Measure the power supply voltage 12VA of the microprocessor power supply JZ024

(PT12 on J4 of the CJ732).

Solution:

Replace the microprocessor power supply JZ024 if defective.

KODAK 9000 and KODAK 9000 3D Extraoral Imaging System_Service Guide (SM712)_Ed 02

7–3

E3: Kv Measurement Problem (Kv High)

E3: Kv Measurement Problem (Kv High)

Definition of the Cause

•

•

The high voltage in the x-ray generator exceeds the specified value.

The microprocessor has detected the fault and has interrupted the x-ray emission to

avoid damage to the x-ray generator.

Solution of the Cause

Possible Cause:

A cable is defective.

Remarks:

Fault Identification:

Check the connecting cable 16/CJ732 on J12 and cable 24/CJ653 on J3 for:

• Electric continuity

• Electric connections

• Cable condition

Solution:

Replace the defective component.

Possible Cause:

The following component have been replaced without being calibrated:

• The CJ732 board

• The x-ray generator

Remarks:

The preheating value is incorrect.

Fault Identification:

Solution:

Possible Cause:

Calibrate the heating voltage.

•

•

The CJ732 board is defective.

The x-ray generator is defective.

Remarks:

Fault Identification:

Solution:

Measurements must be performed on the CJ732 board or/and x-ray generator.

•

•

7–4

ERROR MESSAGES

Replace the CJ732 board.

Replace the x-ray generator.

E4: Kv Measurement Problem (kV Low)

E4: Kv Measurement Problem (kV Low)

Definition of the Cause

•

•

The high voltage in the x-ray generator is inferior to the specified value.

The microprocessor has detected the fault and has interrupted the x-ray emission to

avoid damage to the x-ray generator.

Solution of the Cause

Possible Cause:

A cable is defective.

Remarks:

Fault Identification:

Check the connecting cable 13/CJ732 on J1, cable 16/CJ732 on J12 and cable

24/CJ653 on J3 for:

• Electric continuity

• Electric connections

• Cable condition

Solution:

Replace the defective component.

Possible Cause:

The following component have been replaced without being calibrated:

• The CJ732 board

• The x-ray generator

Remarks:

The preheating value is incorrect.

Fault Identification:

Solution:

Calibrate the heating voltage.

Possible Cause:

The power supply to the unit is 20% lower than the nominal value (see the

identification plate).

Remarks:

The unit is not functioning correctly.

Fault Identification:

Check the following electrical installations:

• The power supply socket voltage measured using a voltmeter

• The wiring to and from the unit

• The section of the cables

Solution:

If fault is detected, the installation must be rendered compliant.

Possible Cause:

One of the CJ653 board F1 or F2 fuses are defective.

KODAK 9000 and KODAK 9000 3D Extraoral Imaging System_Service Guide (SM712)_Ed 02

7–5

E4: Kv Measurement Problem (kV Low)

Remarks:

Fault Identification:

The F1 and F2 fuses protect the power supply of the CJ653 Inverter Board.

•

•

Solution:

•

•

Possible Cause:

•

•

Remarks:

Check the fuses.

If the fuses are burned, check the CJ653 board to see if it is defective.

Replace the fuses.

If necessary, replace the CJ653 board.

The CJ732 board is defective.

The x-ray generator is defective.

Measurements must be performed on the CJ732 board and the x-ray generator.

Fault Identification:

Solution:

•

•

7–6

ERROR MESSAGES

Replace the CJ732 board.

Replace the x-ray generator.

E6: Electric Arc Detection in the Generator

E6: Electric Arc Detection in the Generator

Definition of the Cause

•

•

An electric arc has been generated in the x-ray generator.

The microprocessor has detected the fault and has interrupted the x-ray emission to

avoid damage to the x-ray generator.

Solution of the Cause

Possible Cause:

The x-ray generator is defective

Remarks:

Fault Identification:

Solution:

Acquire 1 or more images at 90kV and 8mA. In many cases, when an electric arc is

generated a click can be heard in the x-ray generator.

•

Replace the x-ray generator.

Possible Cause:

The following component have been replaced without being calibrated:

• The CJ732 board

• The x-ray generator

Remarks:

The preheating value is incorrect.

Fault Identification:

Solution:

Calibrate the heating voltage.

Possible Cause:

The power supply to the unit is 20% lower than the nominal value (see the

identification plate).

Remarks:

The unit is not functioning correctly.

Fault Identification:

Check the following electrical installations:

• The power supply socket voltage measured using a voltmeter

• The wiring to and from the unit

• The section of the cables

Solution:

If fault is detected, the installation must be rendered compliant.

KODAK 9000 and KODAK 9000 3D Extraoral Imaging System_Service Guide (SM712)_Ed 02

7–7

E6: Electric Arc Detection in the Generator

Possible Cause:

If the x-ray generator has not been used for 2 months or more, the x-ray tube may

degas, that means, the gas molecules escape from the x-ray tube.

Remarks:

Fault Identification:

Solution:

You must recreate a vacuum inside the x-ray tube.

To recreate a vacuum inside the x-ray tube, follow these steps:

1. Switch off the unit.

2.

From the fixed arm, on the control panel, press and hold at the same time

,

and turn on the unit.

3. The display screen of the control panel runs a series of initialization messages,

then it indicates Mode: Technical.

4. Access the Panoramic Acquisition Window. Click

Maintenance > Calibration > Tube head calibration.

select

5. Access the Panoramic Acquisition Window, in the Program pane, select

the following parameters:

•

•

•

•

•

•

•

•

•

•

60 kV, 2 mA and make 3 exposures. Wait 10 minutes.

60 kV, 6.3 mA and make 1 exposure.

60 kV, 15 mA and make 2 exposures. Wait 10 minutes.

60 kV, 15 mA and make 1 exposure.

70 kV, 6.3 mA and make 1 exposure.

70 kV, 15 mA and make 1 exposure. Wait 10 minutes.

70 kV, 10 mA and make 1 exposure.

80 kV, 10 mA and make 1 exposure.

90 kV, 10 mA and make 1 exposure.

The end of procedures.

WARNING:

If the x-ray tube contains too much gas, there are risks of arcing, which can be

detected by the unit system. The following error messages could be displayed:

E6, E3, E4, E7, E8, E10.

In this case wait 15 minutes and restart again the procedures.

If after having carried out the procedure 3 times, the error message appears

again, then the x-ray generator is defective. Replace the x-ray generator.

7–8

ERROR MESSAGES

E7: mA Measurement Problem (mA High)

E7: mA Measurement Problem (mA High)

E8: mA Measurement Problem (mA Low)

Definition of the Cause

•

•

The mA values in the x-ray generator is either superior or inferior to the specified

values.

The microprocessor has detected the fault and has interrupted the x-ray emission to

avoid damage to the x-ray generator.

Solution of the Cause

Possible Cause:

A cable is defective.

Remarks:

Fault Identification:

Check the connecting cable 14/CJ732 on J4 and cable 16/CJ732 on J12 for:

• Electric continuity

• Electric connections

• Cable condition

Solution:

Replace the defective component.

Possible Cause:

The following component have been replaced without being calibrated:

• The CJ732 board

• The x-ray generator

Remarks:

The preheating value is incorrect.

Fault Identification:

Solution:

Calibrate the mA values.

Possible Cause:

The value of the supply voltage to the heating circuit is incorrect.

Remarks:

Fault Identification:

Solution:

In this case, the mA values can only be too low (E 8 only).

•

Measure with a voltmeter the supply voltage to the heating circuit PT14 on the

CJ732 board.

WARNING:

This value must be set to 6.5 VDC

• Adjust the voltage.

KODAK 9000 and KODAK 9000 3D Extraoral Imaging System_Service Guide (SM712)_Ed 02

7–9

Download KODAK OPG K9000- 3D ERROR MESSAGE-ed02-en

KODAK OPG K9000- 3D ERROR MESSAGE-ed02-en.pdf (PDF, 666.64 KB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000523603.