Web presentation (PDF)

File information

Title: FileNewTemplate

Author: Diana

This PDF 1.5 document has been generated by Microsoft® PowerPoint® 2013, and has been sent on pdf-archive.com on 13/10/2016 at 23:13, from IP address 4.35.x.x.

The current document download page has been viewed 373 times.

File size: 1.25 MB (14 pages).

Privacy: public file

File preview

Tashi’s Academic Projects

Sensors and Data - UConn Capstone Project

For Web Viewing

04/06/2016

1

Intro for Web Viewers

Hello!

Thanks for taking a moment to check out this short Powerpoint. In it I cover a

few projects that I have worked on during my academic career.

The first project that I cover is a lab assignment that I carried out during my

sophomore year at the University of Connecticut

The second project is my Capstone project from my senior year. The intent of

this web presentation is to give a brief overview of some of the things I have

worked on and where my interests lie.

Thanks for viewing! I am looking forward to giving this presentation to you in

person.

2

Sensors and Data

Piezoelectric Actuator Lab

•

•

•

•

•

Used a motor with a fine travel

range of 25 micrometers

Inputted 5 V signal at 5hz

Measured movement with Linear

Variable Displacement Transducer

(LVDT) and National Instruments

LabView

Used filters to account for noise

Looked for 5hz signal in LabView

3

Sensors and Data

Results

•

•

Focus was on windowing and

signal processing

Used Fourier Transform to find

constituent frequencies of

measured signal

•

•

Various waveforms

Various sampling frequencies

4

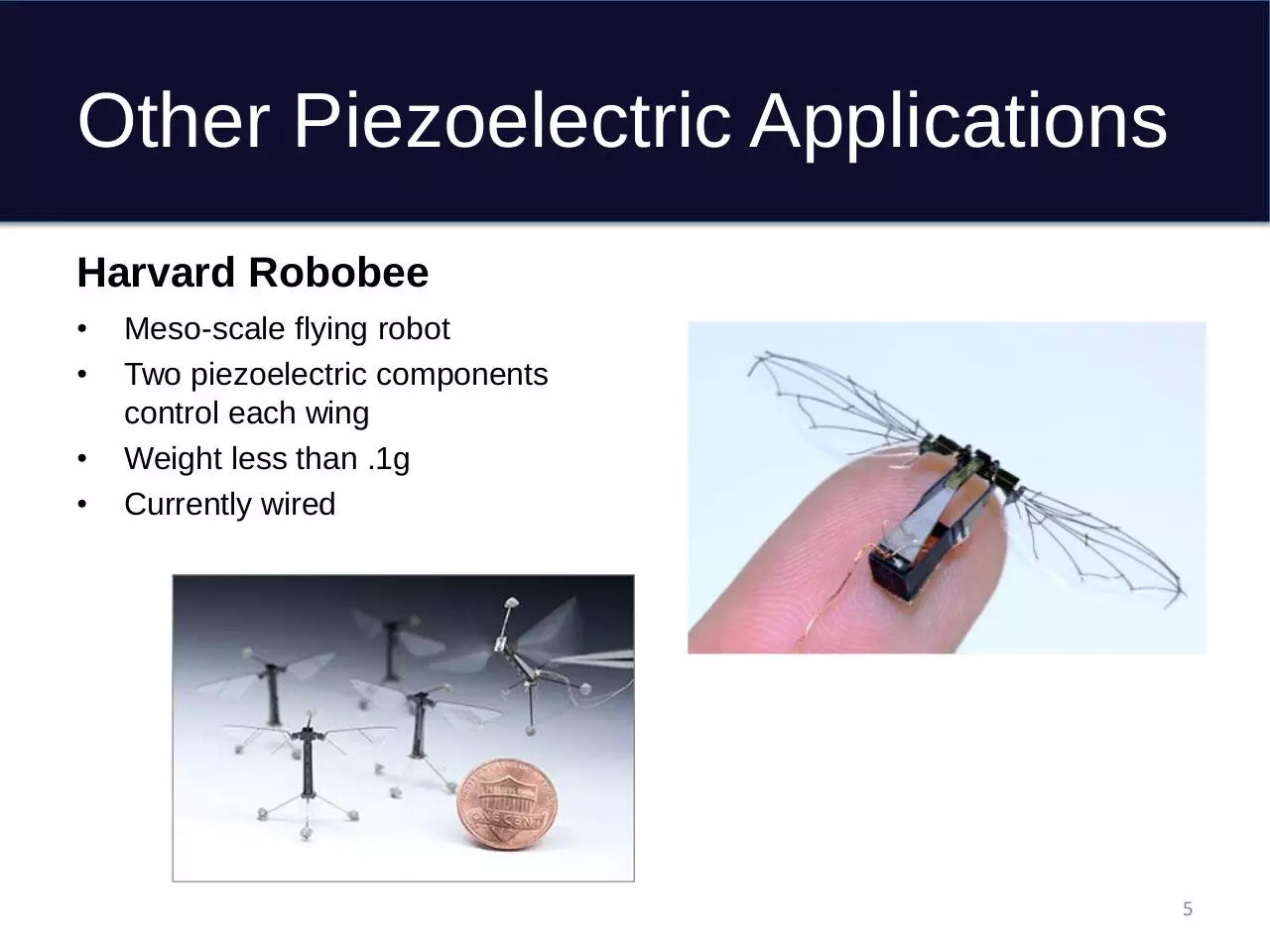

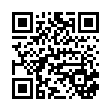

Other Piezoelectric Applications

Harvard Robobee

•

•

•

•

Meso-scale flying robot

Two piezoelectric components

control each wing

Weight less than .1g

Currently wired

5

UConn Senior Design

Overview

•

•

•

•

Year-long design project

Corporate Sponsor

gives “donation” of

~$10,000

Teams of students work

to solve industry

problems

Projects are displayed

at UConn School of

Engineering

“Demonstration Day”

6

Automation of a Taping Process

•

•

•

•

•

Goal was to automate the

application of masking tape

Masked parts to be plated

(chrome, anodized, acid-etching)

MRO process – variable part

geometry

Machine has to accept range of

part sizes

Successful outcome

7

Picture of Final Product – ‘Lathe’

Style Automated Machine

Logic Control

Module

Drive Motor

Power Distribution

Module

Adjustable End

Plate

8

Systems - Moveable End Plate

•

•

•

Anodized aluminum endplate supported by linear bearing on rods.

End plate allows for part lengths of 1” to 30”

Plate held in place by quick clamp

9

Download Web presentation

Web presentation.pdf (PDF, 1.25 MB)

Download PDF

Share this file on social networks

Link to this page

Permanent link

Use the permanent link to the download page to share your document on Facebook, Twitter, LinkedIn, or directly with a contact by e-Mail, Messenger, Whatsapp, Line..

Short link

Use the short link to share your document on Twitter or by text message (SMS)

HTML Code

Copy the following HTML code to share your document on a Website or Blog

QR Code to this page

This file has been shared publicly by a user of PDF Archive.

Document ID: 0000494370.